| –

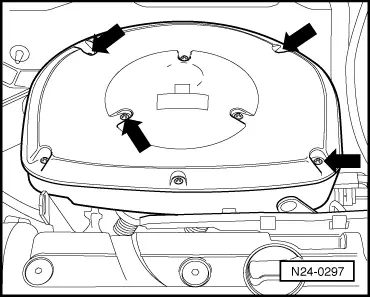

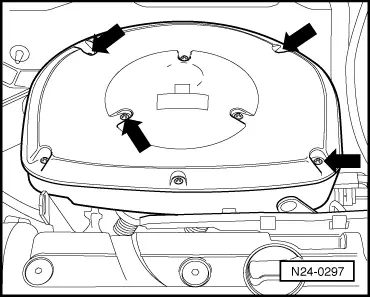

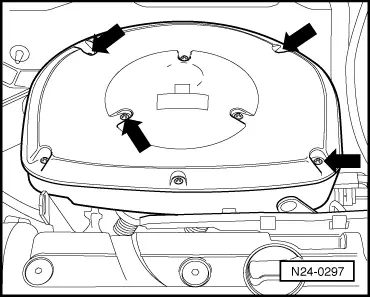

| Remove the air filter. To do so, loosen the bolts marked with -arrows-. |

Note! | t

| When loosening or tightening the securing bolts with an electric/pneumatic screwdriver, the intake hose threads can be damaged. Therefore, only use an electric/pneumatic screwdriver in the following conditions: |

| t

| Maximum screwdriver revolutions: 200 rpm |

| t

| Maximum tightening torque of 3 Nm |

| –

| Remove the spark plugs. |

| –

| Remove the Hall transmitter connector (ignition distributor). |

| –

| Work with another mechanic fully depressing the accelerator pedal. |

| –

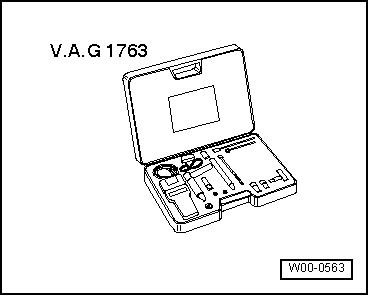

| Check the compression with compression recorder -V.A.G 1381- or -V.A.G 1763-. |

Note! | Operation of the tester is described in its instructions for use. |

| –

| Operate the starter motor until the testing equipment does not mark pressure increase. |

| Allowable difference between all cylinders: 3 bar |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!