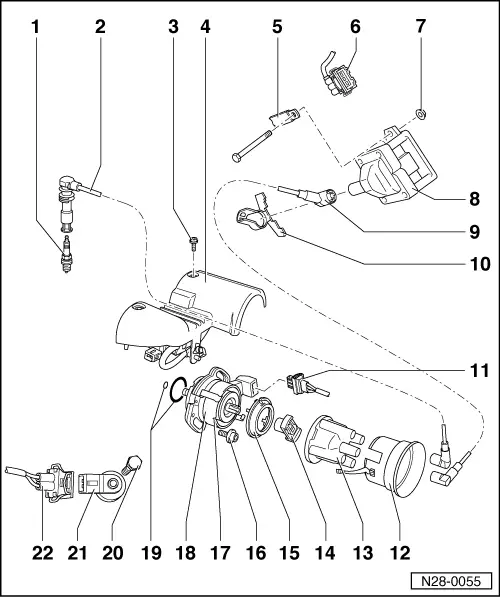

Leon Mk1

| Removing and installing parts of the ignition system |

| 1 - | Spark plug |

| q | 30 Nm |

| q | Type and electrode gap → Chapter |

| q | Removing and installing with -T20028- |

| 2 - | Ignition cable with spark plug connector and suppressor |

| q | Renew complete ignition cable |

| q | Resistance of complete wire 4,6…7,4 kΩ |

| 3 - | Screw |

| q | 10 Nm |

| 4 - | Cover |

| 5 - | Earth strap |

| 6 - | Connector |

| q | Black, 3-pin |

| q | Ignition transformer -N152- |

| 7 - | Nut |

| q | 10 Nm |

| 8 - | Ignition transformer -N152- |

| q | with final output stage -N157- |

| 9 - | Ignition cable with suppressor connector |

| q | Renew complete ignition cable |

| q | Resistance of complete wire 1,2…2,8 kΩ |

| 10 - | Rotating latch |

| 11 - | Connector |

| q | black, 3 pin |

| q | for Hall sender-G40- |

| 12 - | Screening cap |

| 13 - | Distributor cap |

| q | Check for cracks and signs of tracking |

| q | Check contact wear |

| q | Clean before fitting |

| q | Check carbon brush for wear and freedom of movement |

| 14 - | Rotor arm |

| q | Marking: R1 |

| q | 0,6…1,4 kΩ |

| 15 - | Dust cap |

| 16 - | Screw |

| q | 10 Nm |

| 17 - | No. 1 Cyl. marking |

| 18 - | Ignition distributor with Hall sender -G40- |

| q | Dismantling and assembling → Chapter |

| q | Checking and adjusting ignition timing → Vehicle diagnosis, testing and information systemVAS 5051 |

| 19 - | O-ring |

| q | Renew if damaged |

| 20 - | Screw |

| q | 20 Nm |

| q | Tightening torque influences the function of the knock sensor |

| 21 - | Knock sensor 1 -G61- |

| q | Contacts gold plated |

| 22 - | Connector |

| q | Contacts gold plated |