| l

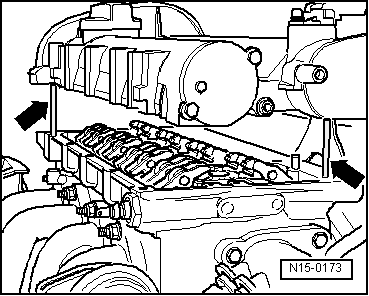

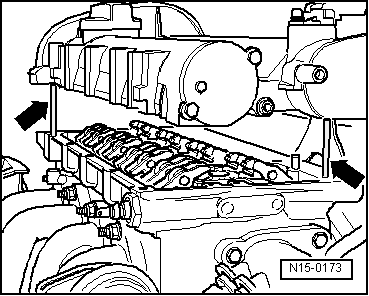

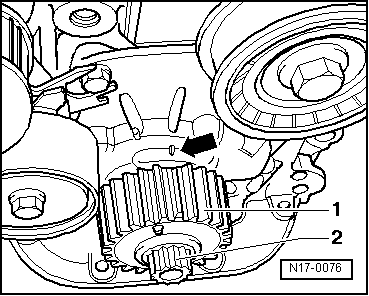

| The pistons must not be positioned at TDC. |

| l

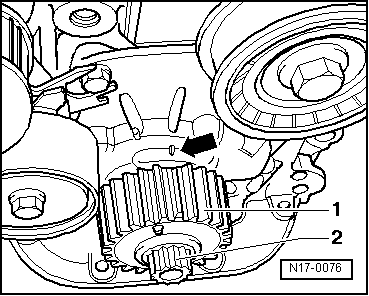

| The crankshaft sprocket must be locked to the crankshaft with a bolt and two washers. |

| l

| The camshaft sprockets, locked in the housing with tool -T10016- and secured against involuntary turning. |

Note! | On turning the camshafts, the valves can hit the pistons if they are at TDC. |

| –

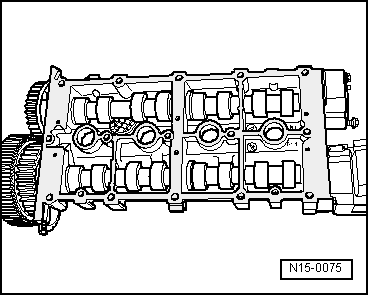

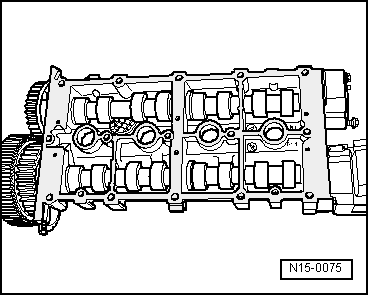

| Remove sealant remnants on cylinder head and camshaft housing with a commercially available flat scraper or commercial sealer remover. |

| –

| Prevent dirt and sealant remnants from entering cylinder head. |

| –

| Contact surfaces must be kept free from oil and grease. |

|

|

|

Note!

Note! Note!

Note!

Note!

Note!

Note!

Note! Note!

Note!

Note!

Note!