| –

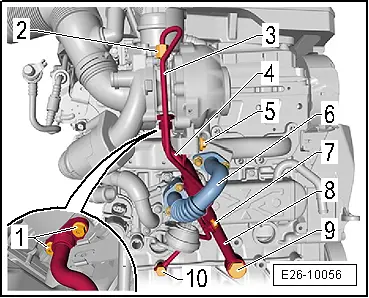

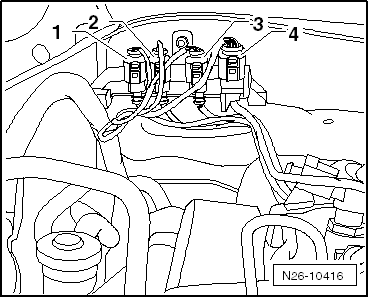

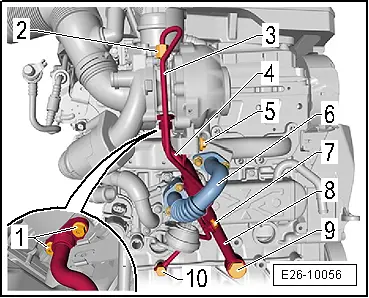

| Remove the connecting pipe -6- for the exhaust gas recirculation. |

| –

| Unscrew the screws of the combined flange -7- that fix the oil supply line on the support of the exhaust gas turbocharger. |

| –

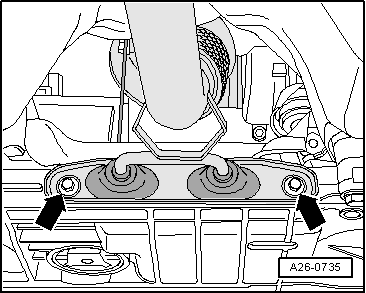

| Place the drip tray -VAS 6208- under the engine. |

| –

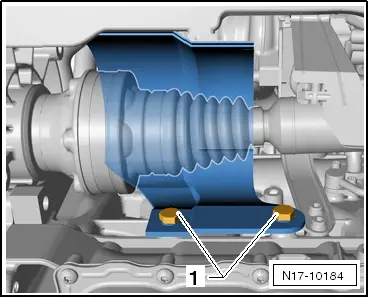

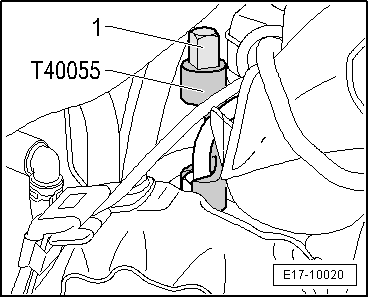

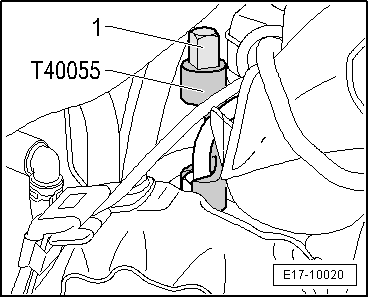

| Unscrew the bolts -1, 5- and the hollow bolts -9, 10-; remove the exhaust gas turbocharger bracket together with the oil return hose. |

| –

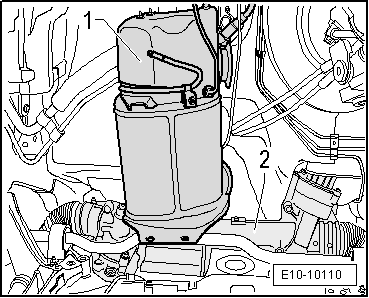

| Remove the combined flange (oil supply and oil return lines) together with the exhaust gas turbocharger supports . |

| –

| Remove oil supply pipe. |

| –

| Remove turbocharger support with oil return pipe. |

Note | t

| After replacing the particulate filter or the pressure differential sender -G505-, the pressure differential sender -G505- must be adapted using the vehicle diagnostics tester -VAS 505xx- in all cases. Guided functions; pressure differential sender -G505-: adapting. |

| t

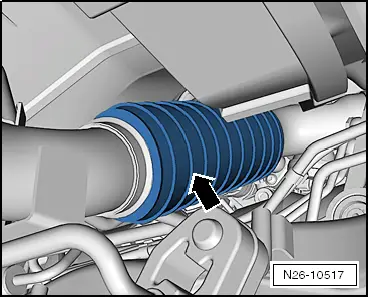

| After working on the exhaust system, ensure that the system is not under stress and that there is sufficient clearance to the bodywork. If necessary, loosen double clamp and align silencer and exhaust pipe so that sufficient clearance is maintained to the bodywork and the support rings are evenly loaded. |

| l

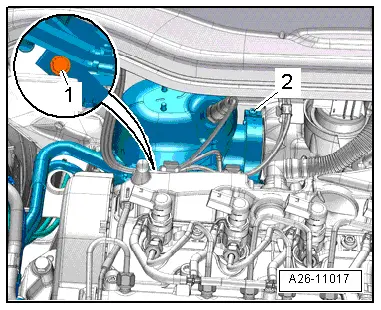

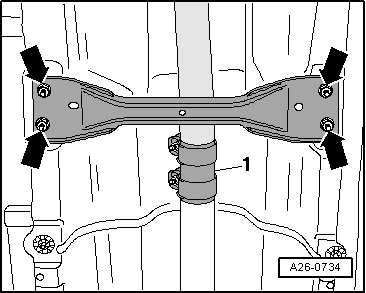

| The work procedure must be followed to ensure that the oil supply/return lines together with the turbocharger support are installed tension-free. |

| l

| Furthermore this ensures that the turbocharger support is installed tension-free between crankcase and turbocharger. |

| –

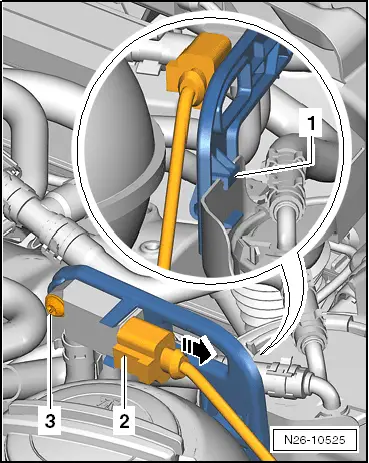

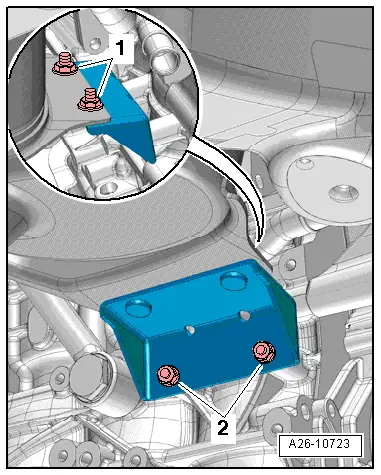

| Position oil return line on turbocharger together with turbocharger support on turbocharger and crankcase. |

| –

| Fit oil supply line onto turbocharger and crankcase. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Caution

Caution