Leon Mk1

|

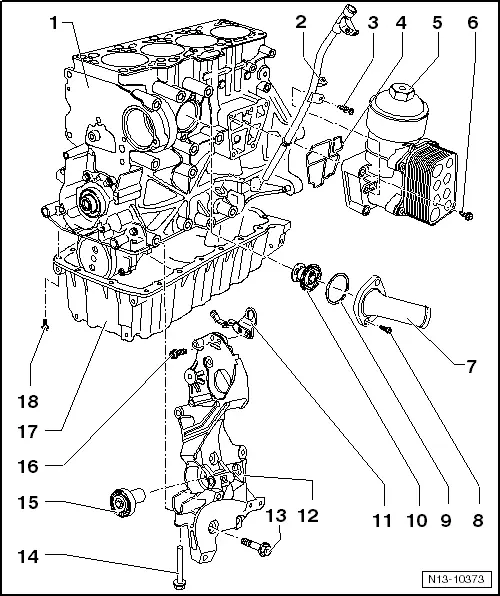

| 1 - | cylinder block |

| q | Removing and installing sealing flange and flywheel → Chapter. |

| q | Removing and installing crankshaft → Chapter. |

| q | Assembly overview - pistons and conrods → Chapter |

| 2 - | Guide pipe |

| q | Renew O-ring. |

| 3 - | Clip |

| 4 - | gaskets |

| q | Replace |

| 5 - | Oil filter bracket |

| q | Assembly overview → Chapter |

| 6 - | 14 Nm and then turn 180° further |

| q | Replace |

| q | First fit the bolts at the top left and bottom right, then tighten all four bolts crosswise |

| 7 - | Joint mouth |

| q | For thermostat |

| 8 - | 13 Nm |

| 9 - | O ring |

| q | Replace |

| 10 - | Coolant thermostat: |

| q | Observe installation position, Removing and installing thermostat → Chapter. |

| q | Check: heat the thermostat in water |

| q | Starts opening at approx. 85 ℃ |

| q | Ends at approx. 105 ℃. |

| q | Opening lift at least 7 mm. |

| 11 - | Attachment rings |

| 12 - | Spring retainer |

| q | For ancillaries |

| 13 - | Bolt. |

| Tightening torque / turning further angle → Chapter |

| 14 - | 30 Nm + 90° |

| q | Replace |

| l | Tightening sequence of the idler roller screw: → Anchor |

| 15 - | Idler roller with bolts |

| 16 - | 25 Nm |

| 17 - | Oil pan |

| q | Clean sealing surface before installing |

| q | Install with silicone sealant -D 176 404 A2-. |

| 18 - | 15 Nm |

Caution

Caution