| Insert the sealing flange with the sender wheel |

Note | t

| The sealing flange with the PTFE seal is fitted with a pressure ring on the sealing lip. This support ring acts as an assembly sleeve and must not be removed before installation. |

| t

| Once unwrapped, do not separate the sealing flange and the sender wheel or modify the position. |

| t

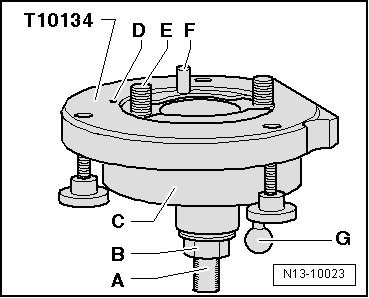

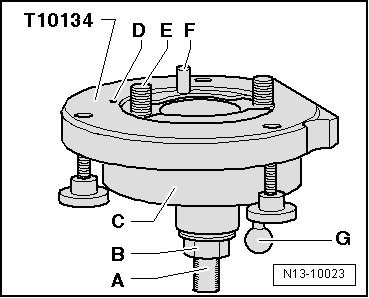

| The sender wheel finds its position automatically when fitted to the position pin of the centre guide -T10134-. |

| t

| The sealing flange and the seal make up one inseparable component and can only be replaced along with the sender wheel. |

| t

| The centre guide -T10134- is held in its installation position for the crankshaft by a guide pin which is inserted into a hole on the crankshaft. |

|

|

|