| –

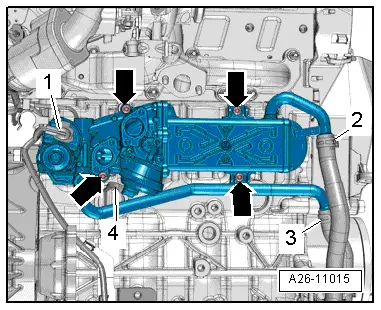

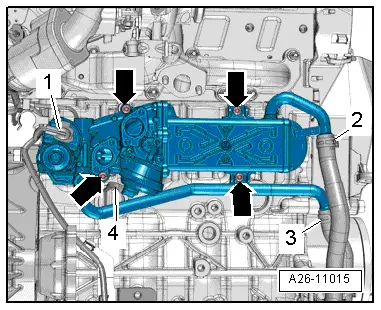

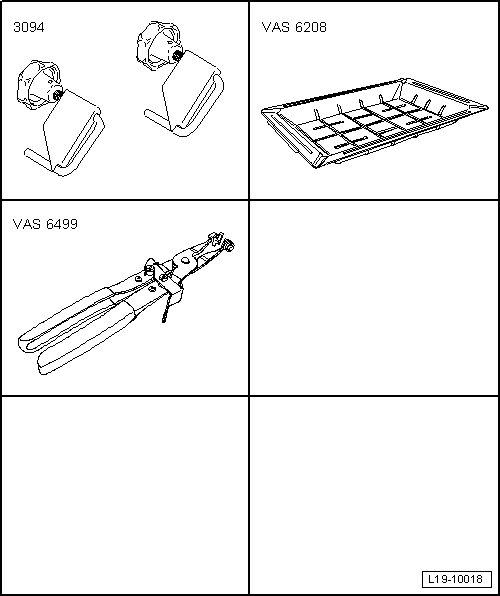

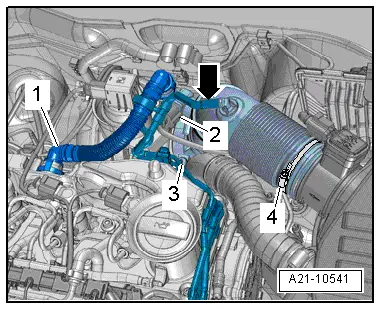

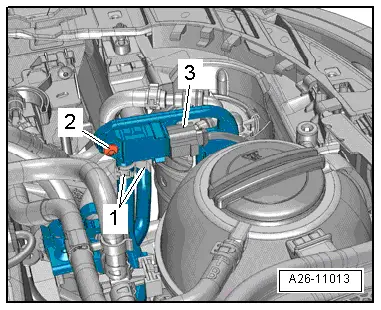

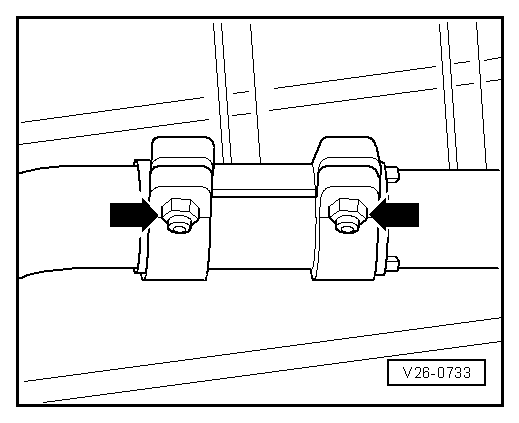

| Clamp off the coolant hoses -2, 3- with hose clamps -3094- and detach hoses from the exhaust gas recirculation radiator. For this purpose loosen the hose clamp. |

| –

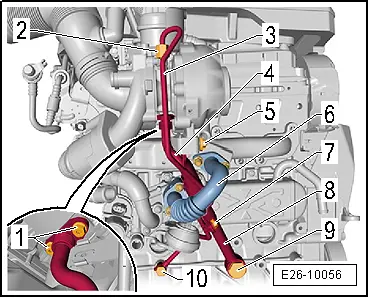

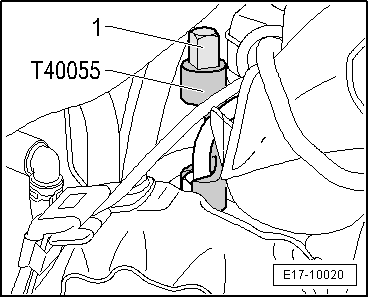

| Disconnect connector -1-. |

| –

| Disconnect vacuum hose -4- from the vacuum switch and move clear. |

| –

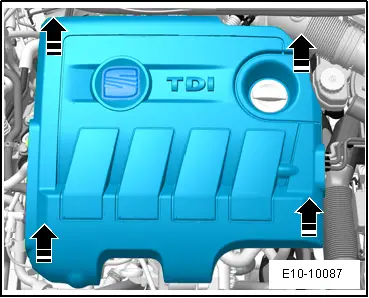

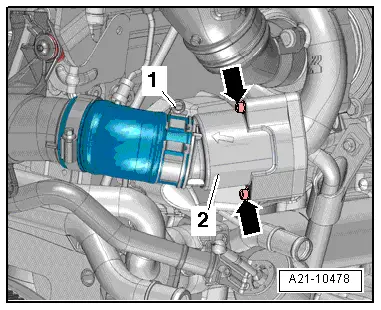

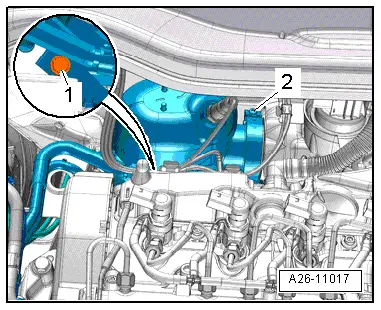

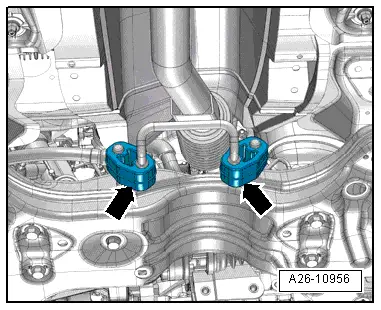

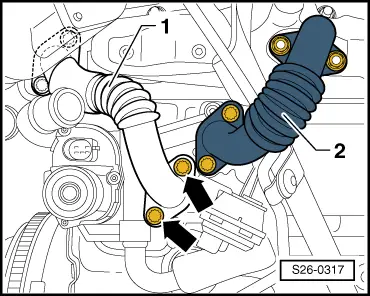

| Remove bolts -arrows- and detach the radiator for the exhaust gas recirculation. |

| Installation is carried out in reverse order, noting the following: |

Note | t

| After removing and installing the particulate filter or the pressure differential sender -G505-, the pressure differential sender -G505- must be adapted using the → Vehicle diagnostic tester in all cases. Guided functions; pressure differential sender -G505-: adapting. |

| l

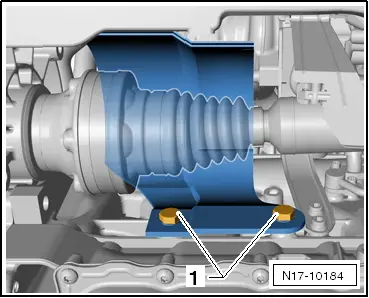

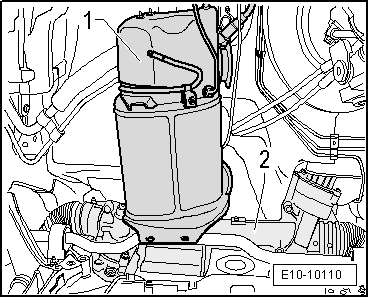

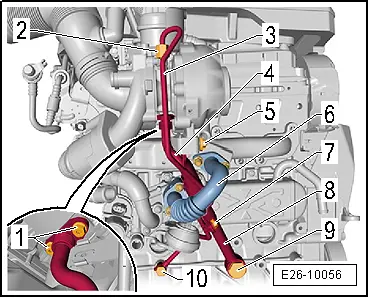

| The work procedure must be followed to ensure that the oil supply/return lines together with the turbocharger support are installed tension-free. |

| l

| Furthermore this ensures that the turbocharger support is installed tension-free between crankcase and turbocharger. |

| –

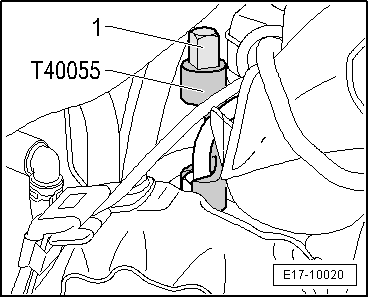

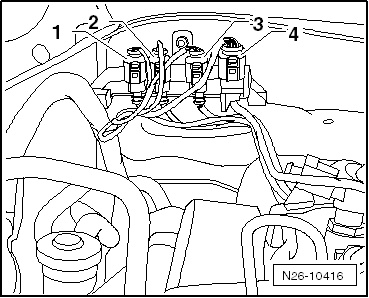

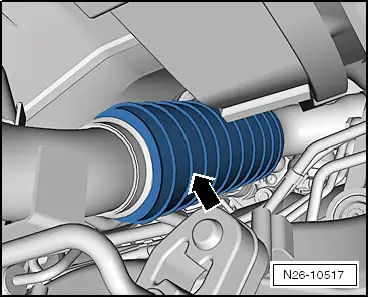

| Position oil return line on turbocharger together with turbocharger support on turbocharger and crankcase. |

| –

| Fit oil supply line onto turbocharger and crankcase. |

|

|

|

Note

Note

Note

Note