Leon Mk1

| Removing and installing sealing flange - pulley end |

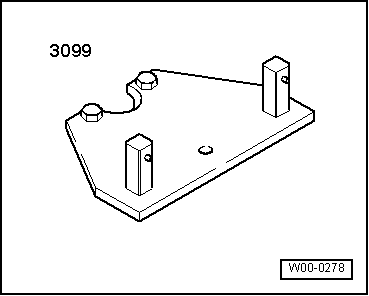

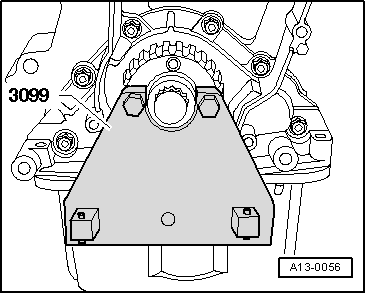

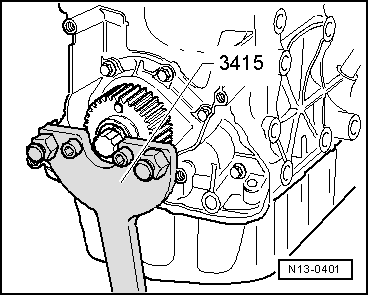

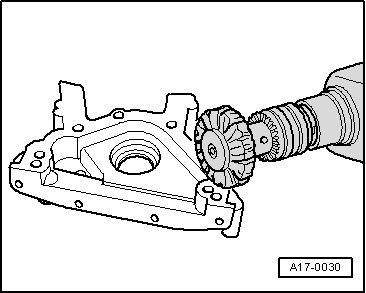

| Special tools and workshop equipment required |

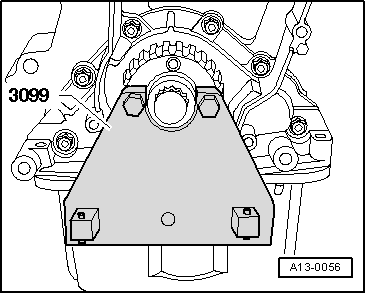

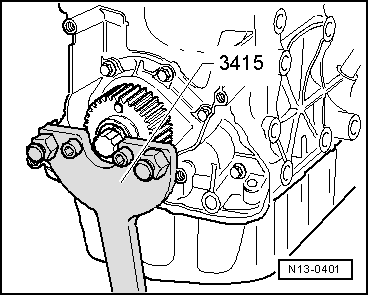

| t | Counterhold tool -3415- (only vehicles 06.00 ►) |

| t | Assembly tool -T10053- |

| t | Torque wrench (5... 50 Nm) -V.A.G 1331- |

| t | Torque wrench (40... 200 Nm) -V.A.G 1332- |

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

WARNING

WARNING