| –

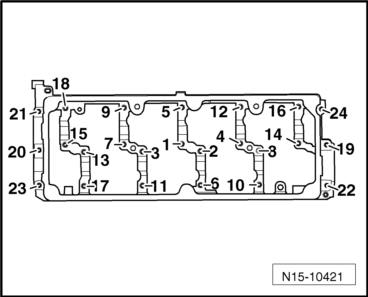

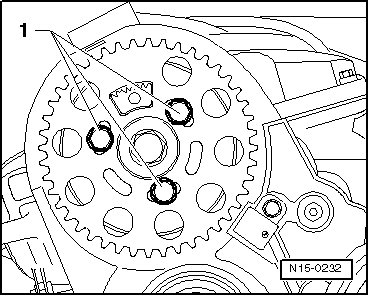

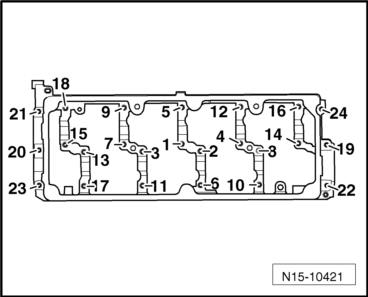

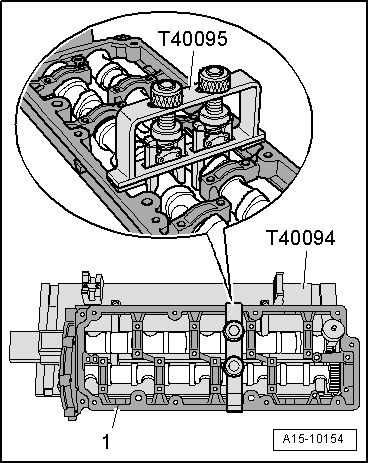

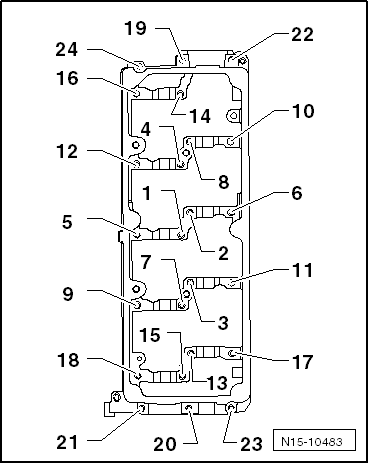

| Unscrew the securing bolts of the bearing cap module in the following sequence: -24 ... 1-. |

| –

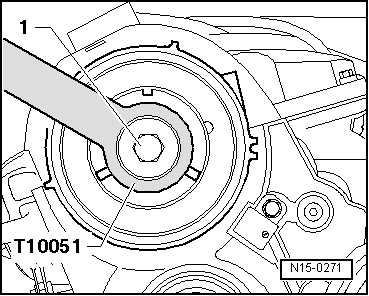

| Remove the bearing cap module. |

| –

| Take out camshafts carefully. |

Note | t

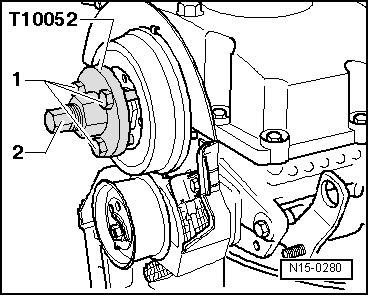

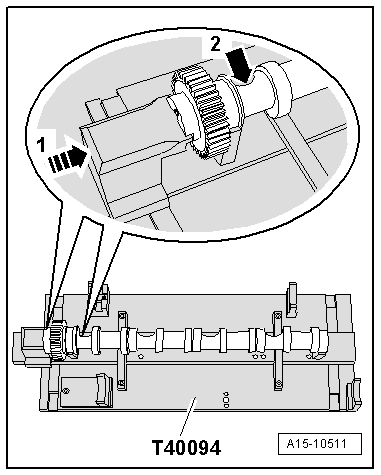

| When installing the camshafts, the cams of cylinder 1 should be pointing upwards. |

| t

| Do not interchange used bearing shells (mark). |

| t

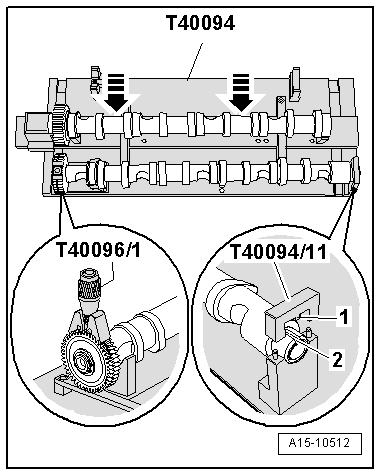

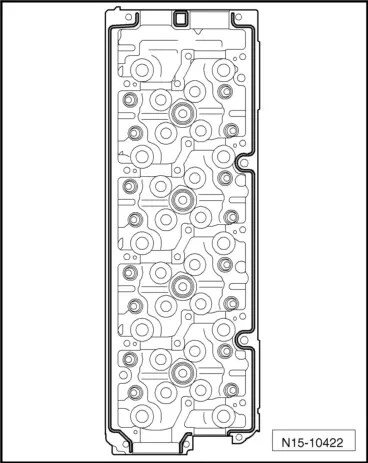

| When fitting the camshaft, ensure that the securing lugs of the half bearing in the bearing cap module and cylinder head are correctly seated. |

| t

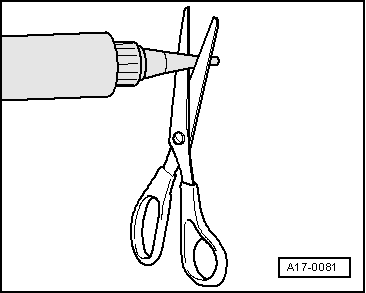

| Seal the contact surface between the bearing cover module and the cylinder head using silicone → Spare parts catalogue. |

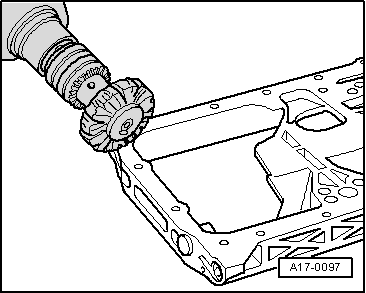

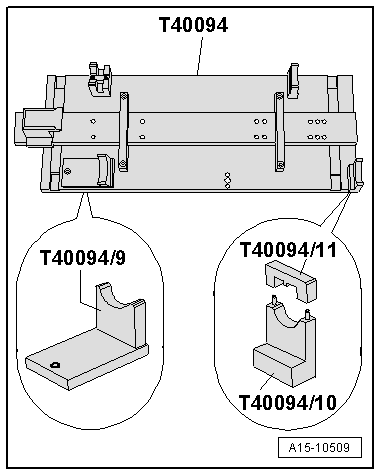

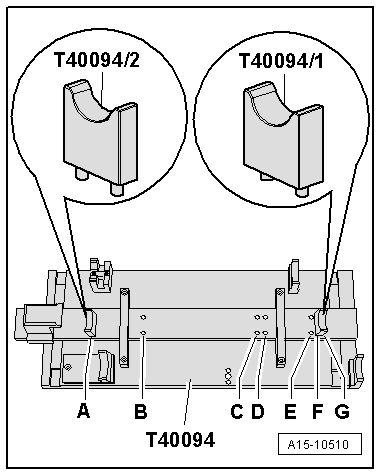

Caution | The camshafts may be attached as described below and only with the Camshaft fitting tool -T40094A-. Otherwise the axial bearings of the bearing cap module could be damaged, as a result of which the cylinder head would have to be replaced. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution