| Checking hydraulic compensation elements |

Note | t

| Hydraulic compensation elements cannot be serviced. |

| t

| Irregular valve noise during starting is normal. |

| Special tools and workshop equipment required |

| –

| Start engine and run until the radiator fan has switched on once. |

| –

| Increase engine speed to about 2500 rpm for 2 minutes; perform road test if necessary. |

Note | If the irregular valve noises stop but recur repeatedly during short journeys, the oil retention valve must be renewed. The oil retention valve is located in the oil filter bracket → Item. |

| –

| If the hydraulic compensation elements are still noisy, find out which is the defective compensation element as follows: |

| –

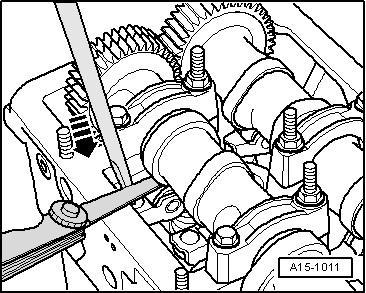

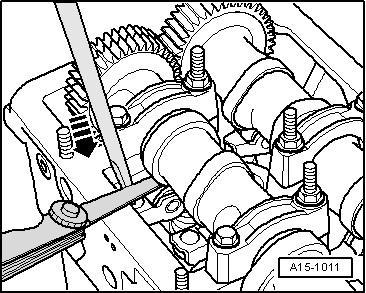

| Turn crankshaft by the bolt for the toothed belt wheel until cam of supporting element to be tested is facing upwards. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note