| –

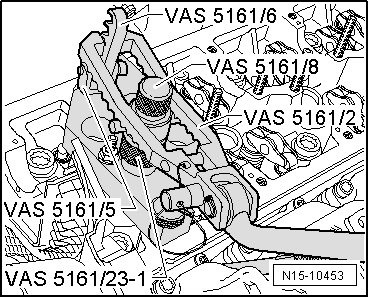

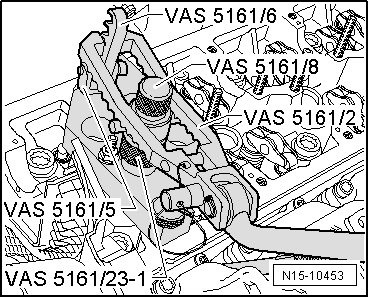

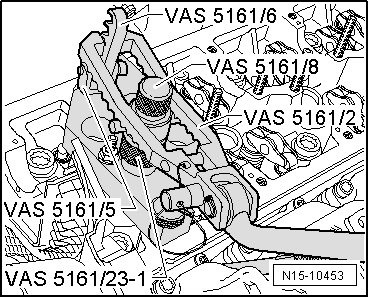

| Screw attachment fork -VAS 5161/5- with ratchet piece -VAS 5161/6- into guide plate. |

| –

| Push knurled spacer ring -VAS 5161/23-1- onto the assembly cartridge -VAS 5161/8-. |

| –

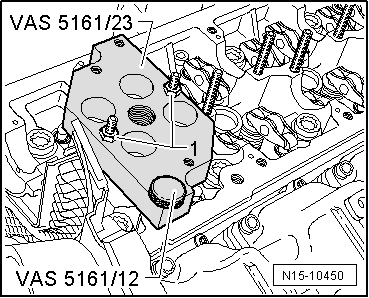

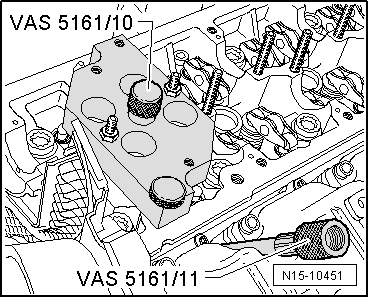

| Connect the adapter -VAS 5161/11- to compressed air with a conventional intermediary piece and supply compressed air continuously. |

| –

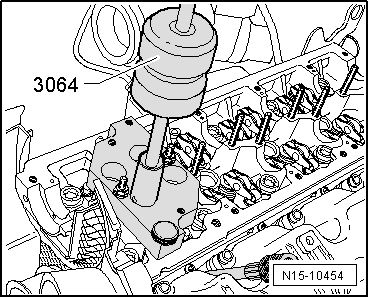

| Connect the pressure fork -VAS 5161/2- of the tool and press the assembly cartridge downwards. |

| –

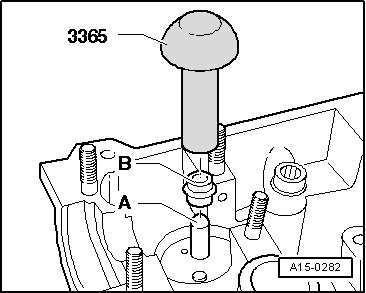

| At the same time, turn the knurled screw of assembly cartridge to the right until the tips engage in valve collets. |

| –

| To disengage the cotter from the valves, move the knurled screw a little and mount the cotter in the assembly cartridge. |

| –

| Release the pressure prong. |

| –

| Remove the assembly cartridge with a knurled spacer ring, valve head and valve spring. |

|

|

|

Note

Note

Note

Note

Note

Note