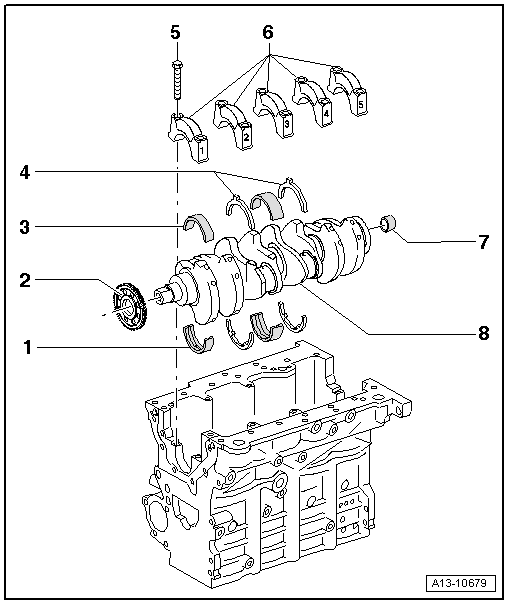

Leon Mk1

| 1 - | Bearing cap |

| q | For cylinder block (with oil groove) |

| q | Mark used bearing shells for re-installation but not on bearing surface |

| 2 - | Cylindrical pinion |

| q | Replace → Chapter |

| 3 - | Bearing cap |

| q | For bearing cap (without oil groove) |

| q | Mark used bearing shells for re-installation but not on bearing surface |

| 4 - | Thrust washer |

| q | For bearing cap 3. |

| q | Various versions for cylinder block and bearing cap. |

| q | Note attachment |

| 5 - | 65 Nm + 90° (1/4 turn) |

| q | Replace |

| q | To measure radial play, tighten to 65 Nm, without retightening |

| 6 - | Bearing cap |

| q | Bearing cap 1: belt pulley end. |

| q | Bearing cap 3 with recesses for thrust washers |

| q | Bearing shell retaining lugs in cylinder block and bearing caps must align. |

| 7 - | Needle bearing |

| q | For vehicles with manual gearbox |

| q | extract and drive in |

| 8 - | Crankshaft |

| q | New axial play: 0.07...00.17 mm Wear limit: 0.37 mm |

| q | Check radial play with plastigage again, new: 0.03 to 0.08 mm; Wear limit: 0.17 mm |

| q | Do not rotate crankshaft when checking radial clearance. |

| q | Crankshaft dimensions → Chapter |

Note

Note