| –

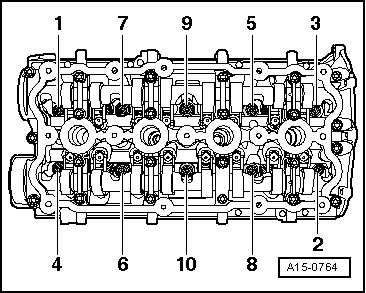

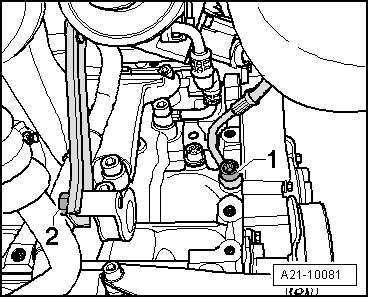

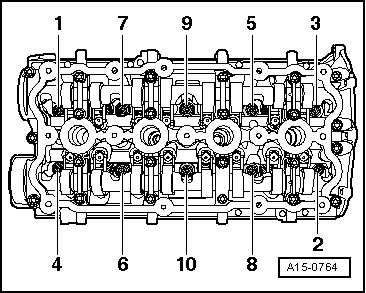

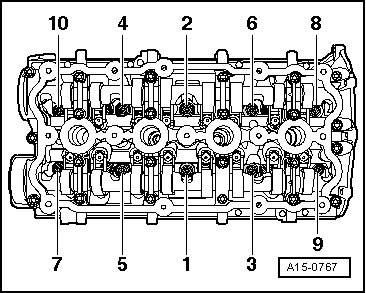

| Loosen the cylinder head bolts in the specified order. |

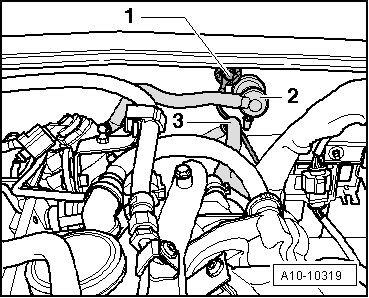

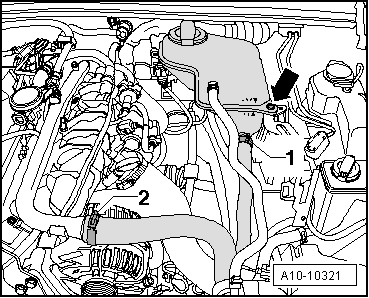

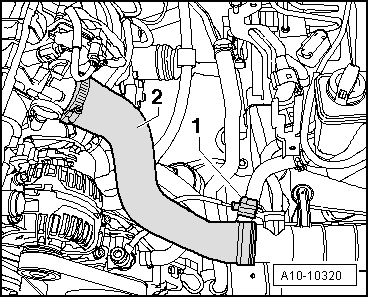

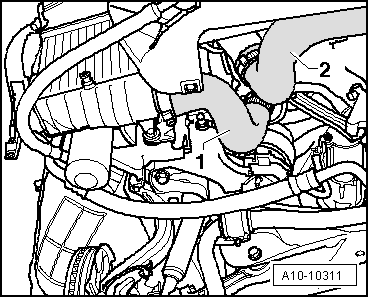

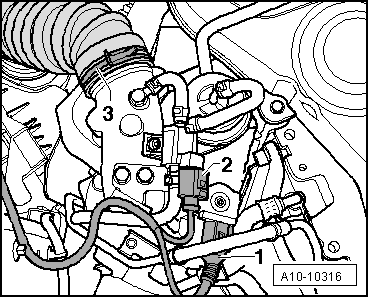

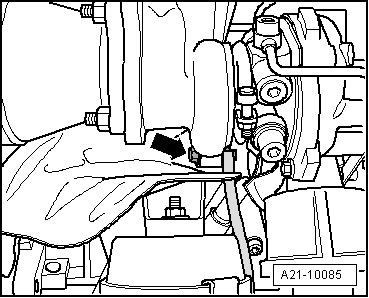

Note | Check that all hose and line connections between engine, gearbox and body have been detached. |

| –

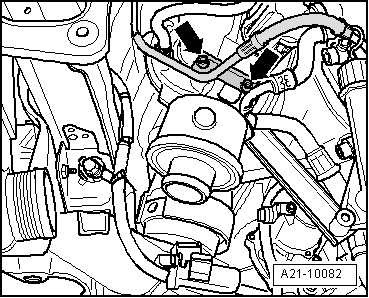

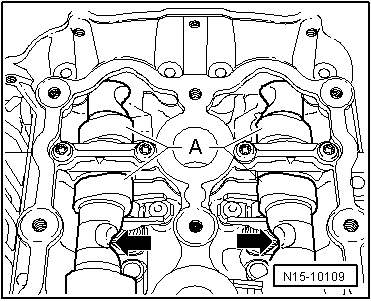

| Remove the cylinder head. |

Note | t

| Renew the cylinder head bolts. |

| t

| On assembling, replace self-locking nuts, bolts subject to goniometric tightening, as well as o-rings and gaskets. |

| t

| If repairing, carefully remove any remains of gasket material from the cylinder head and cylinder block. See that it does not cause any grooves or scratches. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

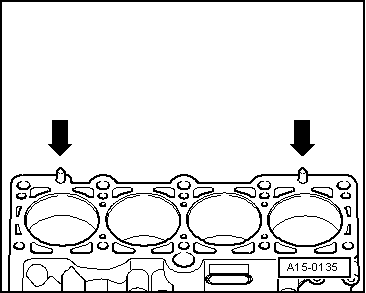

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle gasket extremely carefully. Damaging the silicone layer or the indented area will lead to leaks. |

| t

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

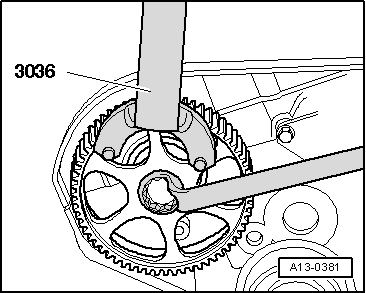

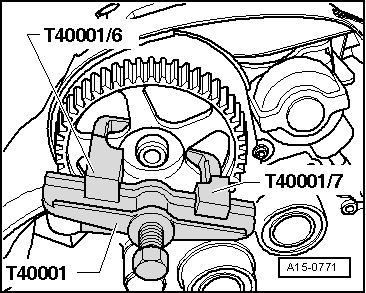

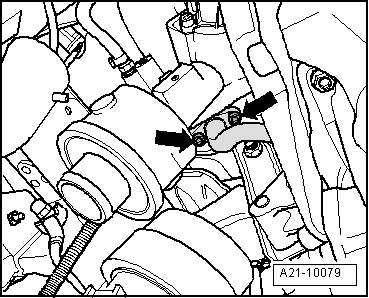

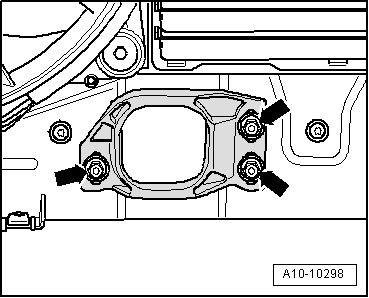

WARNING | The engine must only be rotated by turning the crankshaft in the normal rotation direction (clockwise). |

|

Note | The engine should revolve around the central bolt of the crankshaft. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note

Note

Note Note

Note

WARNING

WARNING