Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

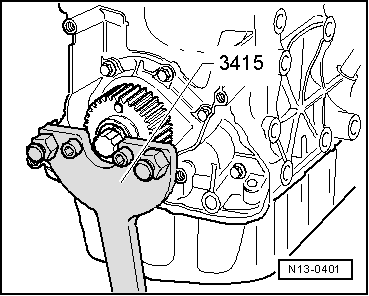

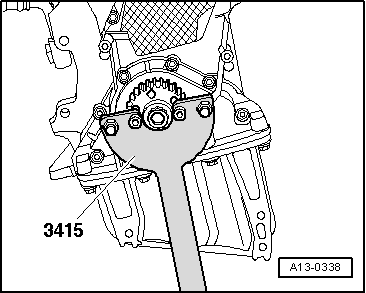

| t | Hose clamp -3415-, see equivalent → Anchor |

| t | Guide sleeve -T10053-, see equivalent → Anchor |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Torque wrench -V.A.G 1332-, see equivalent → Anchor. |

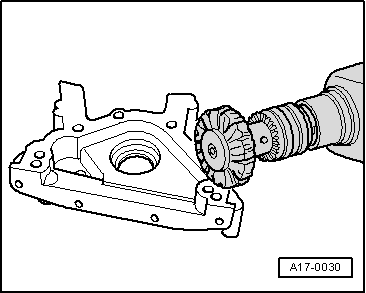

| t | Electric drill with plastic brush attachment |

| t | Flat scraper |

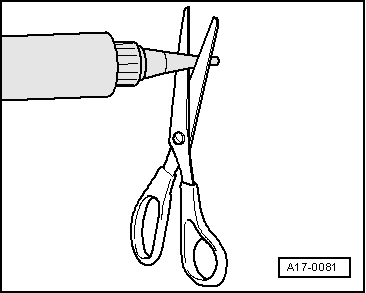

| t | Silicone sealant → Spare parts catalogue |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

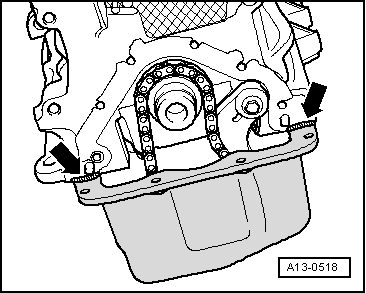

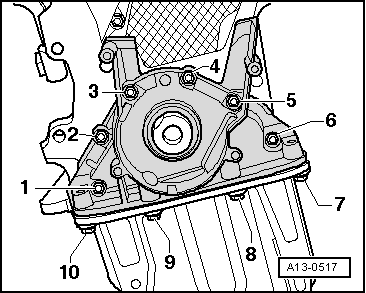

| Components: | Nm | |

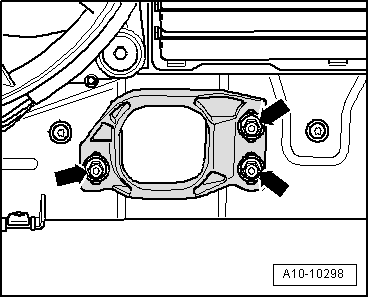

| Sealing flange to cylinder block | 15 | |

| Notched belt sprocket to crankshaft | 90 + 90° → Remark2) |

Note

Note

|

WARNING

WARNING