| –

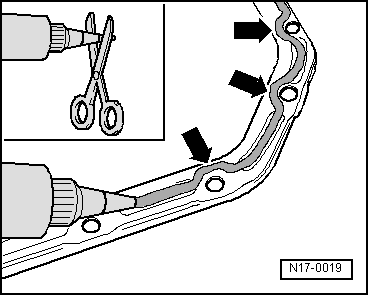

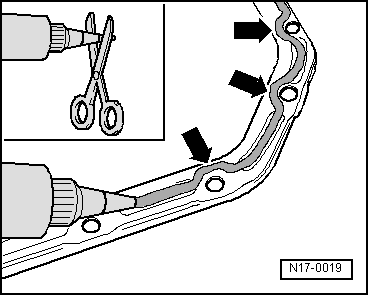

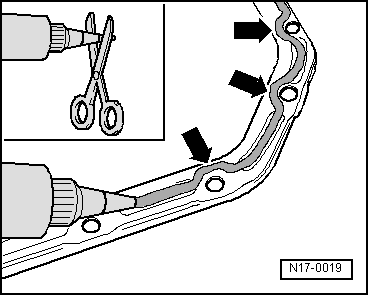

| Cut nozzle off tube at front marking (Ø nozzle diameter approx. 3 mm). |

| –

| Apply the silicone-based sealant to the clean contact surface of the oil sump, proceeding as shown. The strip of sealant must: |

| t

| have a thickness of 2 ... 3 mm |

| t

| Apply along the inner edge of the bolt holes -arrows-. |

Note | The sealant bead must not be thicker. Otherwise the excess sealant may enter the oil sump, and obstruct the strainer in the oil intake pipe. |

| –

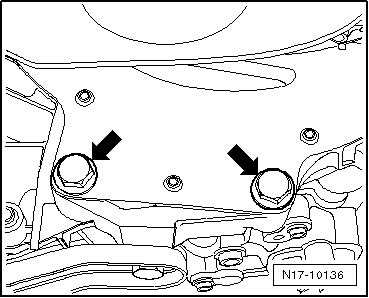

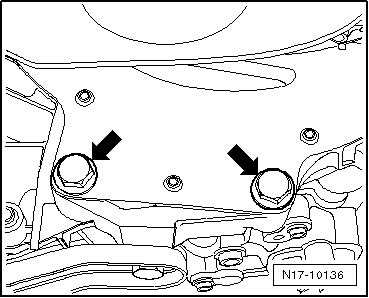

| Fit the oil sump immediately tightening all of the oil sump bolts slightly. |

| –

| Tighten the bolts of the oil sump to 13 Nm. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note