| –

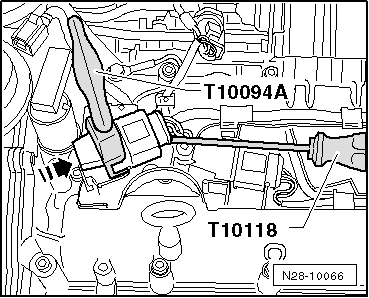

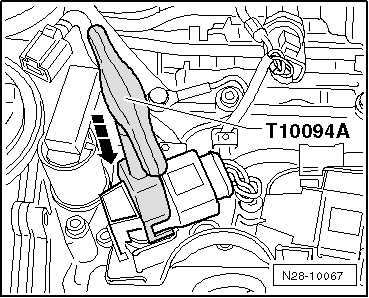

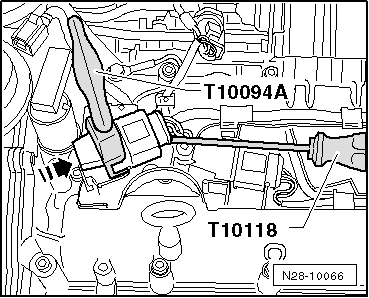

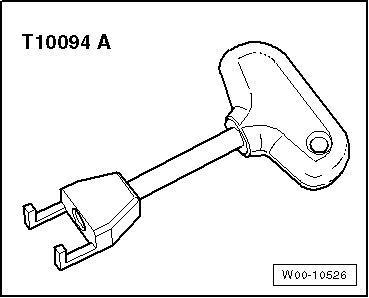

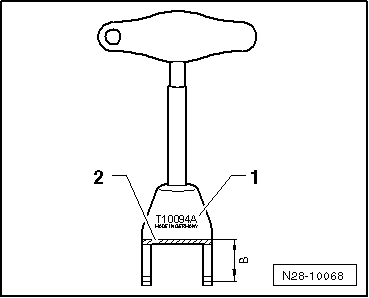

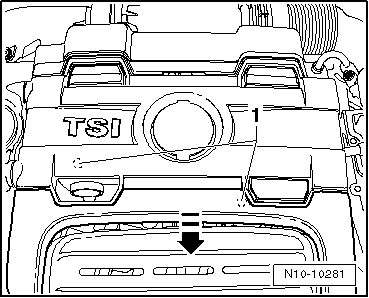

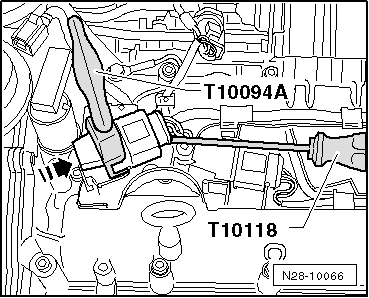

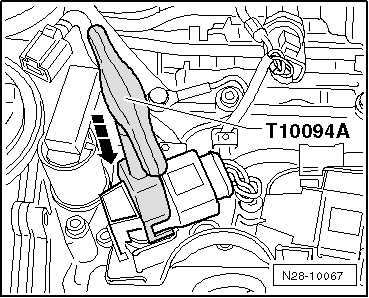

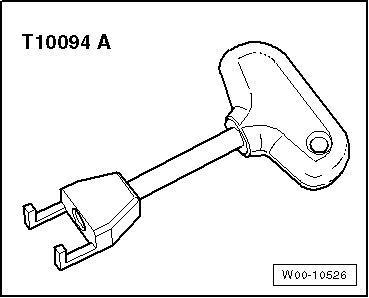

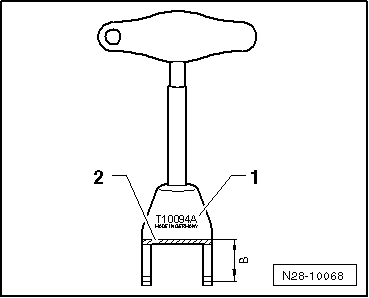

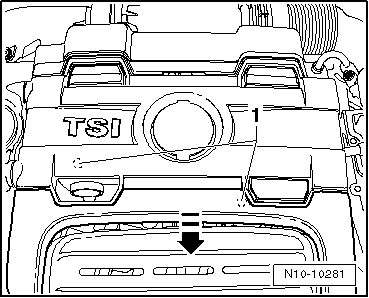

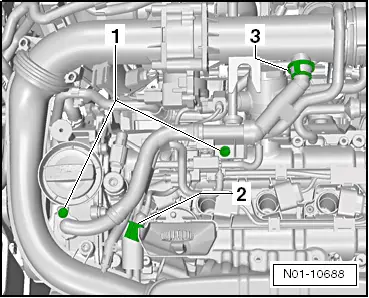

| Fit puller -T10094 A- on ignition coil with final output stage -arrow-. |

| –

| Pull ignition coil with output stage out slightly. |

| –

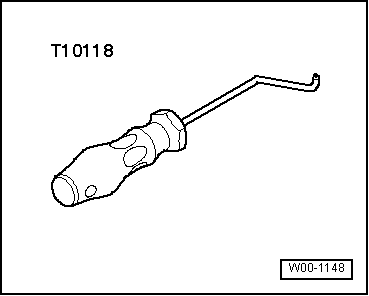

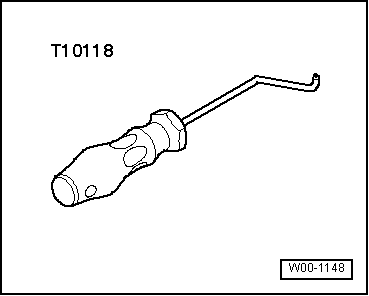

| Fit assembly tool -T10118- as shown. |

| –

| Carefully release catch on connector and unplug connector. |

Note | t

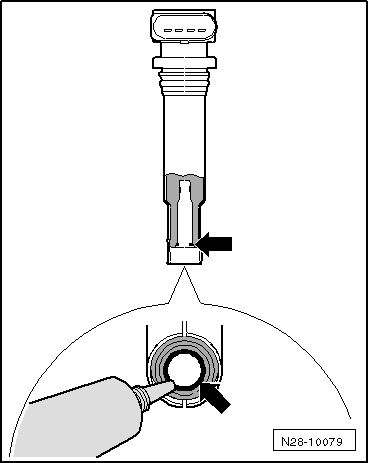

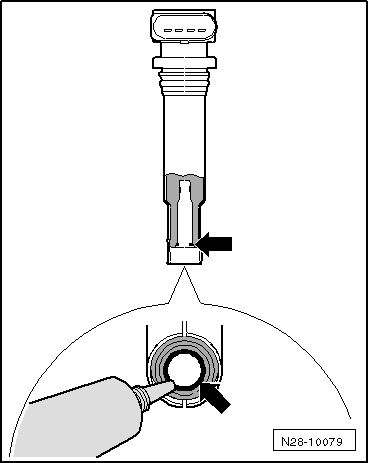

| When fitting new spark plugs, the ignition coil must be regreased using lubricating paste -G 052 141 A2- This will stop the ignition coil sealing hose from »sticking« to the spark plug. The lubricating paste must be distributed on the spark plug when inserting on the ignition coil. |

| t

| New ignition coils with output stage are lubricated when delivered. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note