| –

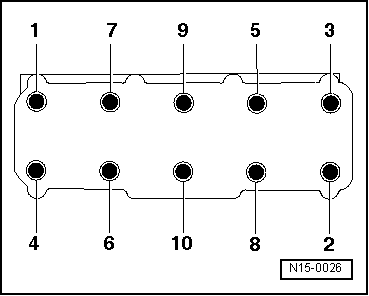

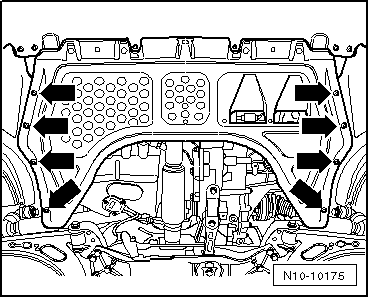

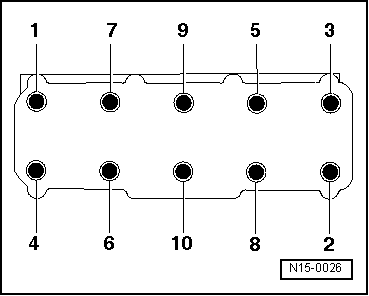

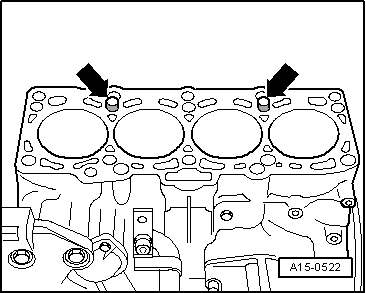

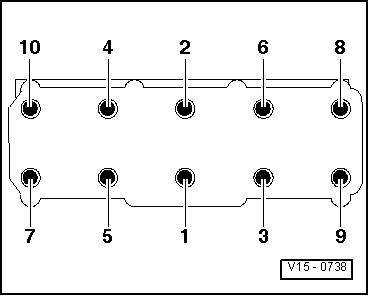

| Loosen the cylinder head bolts in the order given and then remove them. |

| –

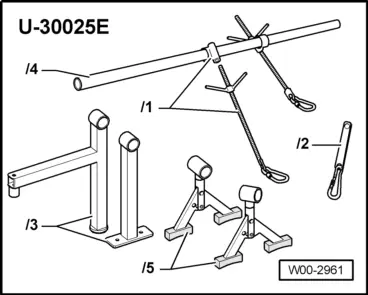

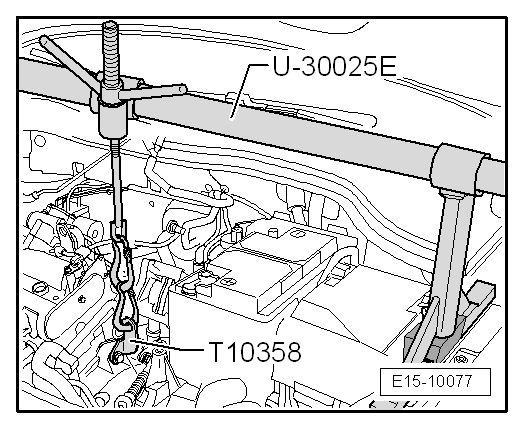

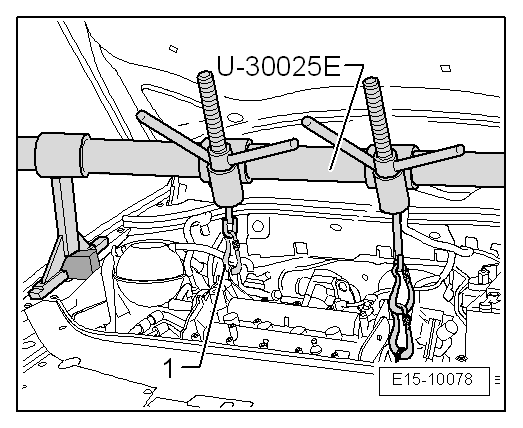

| Lift the cylinder head out with the help of a second mechanic. |

| –

| Place the cylinder head on a soft surface with the combustion chamber side facing up. |

Note | t

| Carefully remove any remains of sealant from the cylinder head and cylinder block. Ensure that no scoring or scratching is produced. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

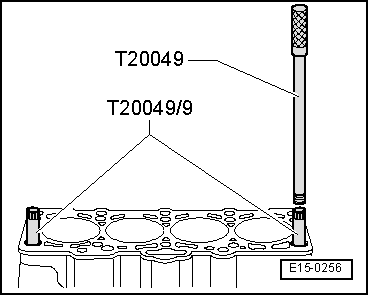

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| t

| The hoses must be free of oil and grease before fitting. |

| t

| Renew cylinder head bolts. |

| t

| When fitting, replace the self-locking nuts and bolts. |

| t

| Renew bolts which have a specified tightening angle, as well as seals and gaskets. |

| t

| Do not remove the new gasket from its packaging until just before fitting. |

| t

| Handle gasket extremely carefully. Damaging the silicone layer or the indented area will lead to leaks. |

| t

| When fitting a new cylinder head with the camshafts fitted, the contact surfaces between the roller rocker arms and the cam contact surfaces must be oiled following the fitting of the cylinder head. |

| t

| The plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| t

| Secure all hose connections with the correct hose clips (same as original equipment) → Parts catalogue. |

| t

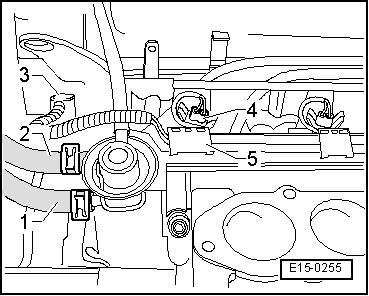

| Before fitting the cylinder head, locate crankshaft at TDC, cylinder 1. |

| –

| Place a clean cloth in cylinders so that no dirt or particles can get in between cylinder wall and piston. |

| –

| Also prevent dirt and particles from getting into the coolant. |

| –

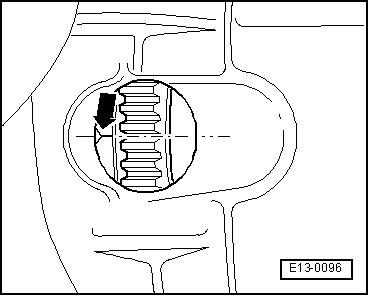

| Carefully clean cylinder head and cylinder block sealing surfaces. Ensure no long grooves or scratches are produced (if using sandpaper, it must be at least 100 grain). |

| –

| Carefully remove any abrasive metal particles and then the cloths. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING