| –

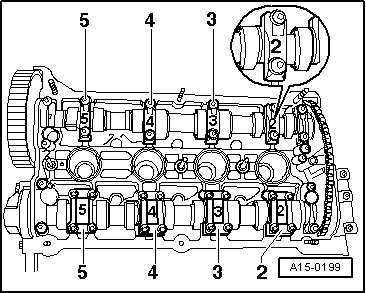

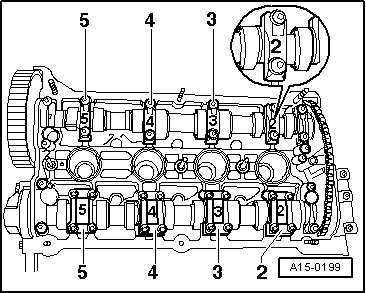

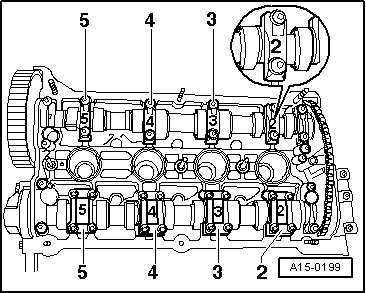

| First remove 3rd and 5th bearing caps from inlet and exhaust camshafts. |

| –

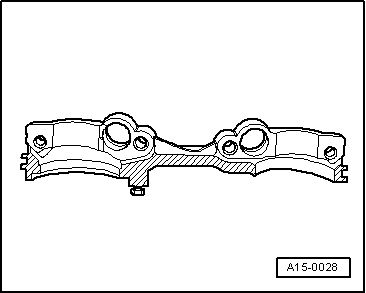

| Remove double bearing cap. |

| –

| Remove both bearing caps at chain sprockets on inlet and exhaust camshafts. |

| –

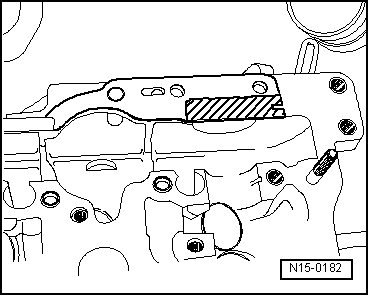

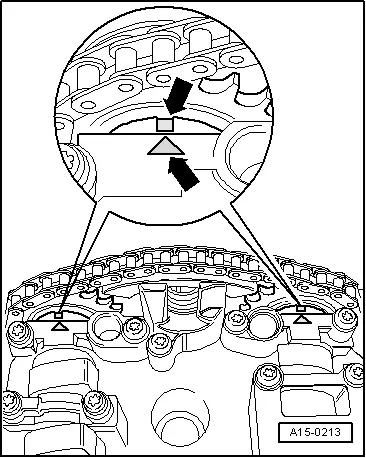

| Remove chain tensioner securing bolts. |

| –

| Remove 2nd and 4th bearing caps from inlet and exhaust camshaft alternately and diagonally. |

| –

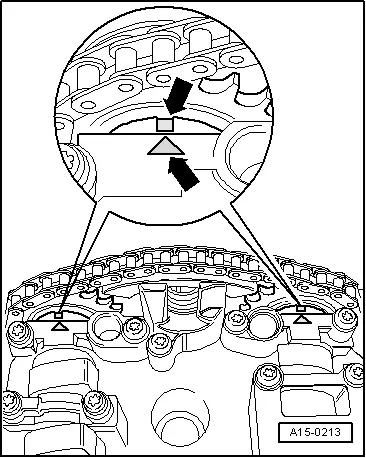

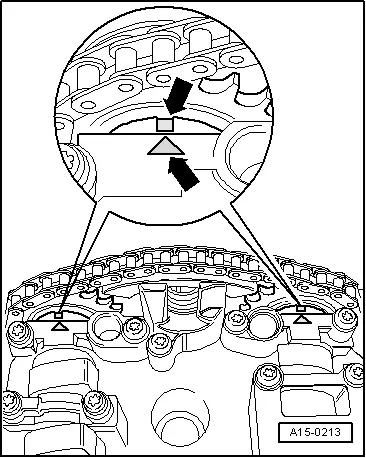

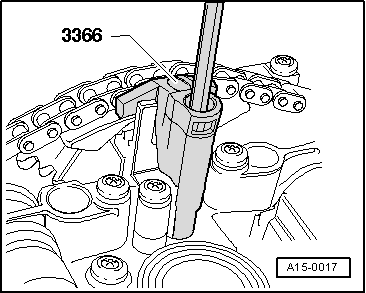

| Remove inlet and exhaust camshaft chain tensioner and chain tensioner retainer -3366-. |

Note! | t

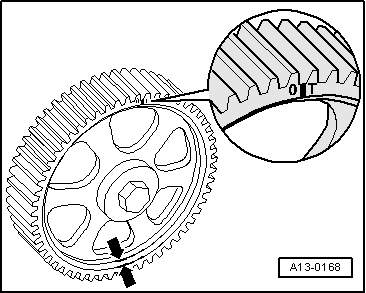

| When camshafts are installed, cams for No. 1 cylinder must point upwards. |

| t

| When installing the bearing caps, ensure that the cap markings can be read from the inlet side of the cylinder head. |

| –

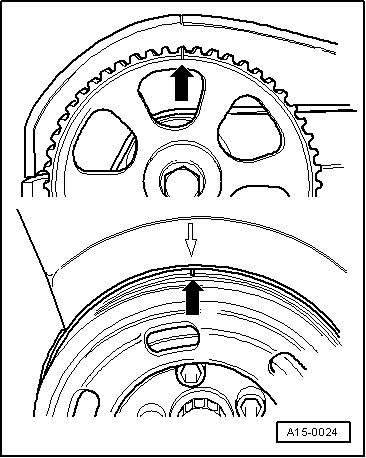

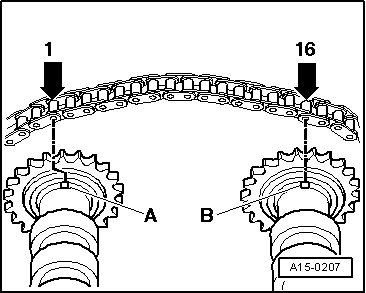

| Fit chain onto both camshafts corresponding to coloured markings. |

Note! |

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note! Note!

Note!

Note!

Note!