Leon Mk1

|

|

|

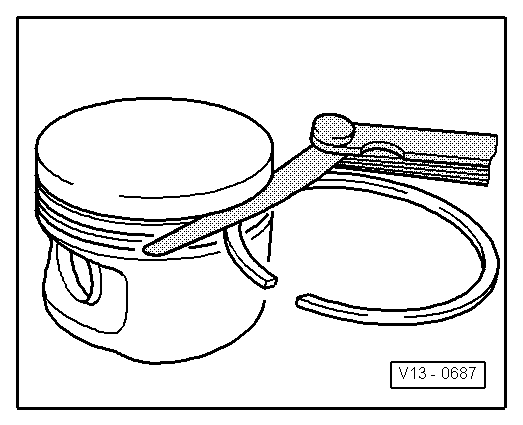

| Piston ring | Gap | ||

| New | Wear limit | ||

| Compression rings | mm | 0.20…0.40 | 0.80 |

| Oil scraper ring | mm | 0.25…0.50 | 1.00 |

|

|

| Piston ring | Ring-to-groove clearance | ||

| New | Wear limit | ||

| Compression rings | mm | 0.02…0.07 | 0.12 |

| Oil scraper ring | mm | 0.02…0.06 | 0.12 |

Note!

Note!

|

|