| –

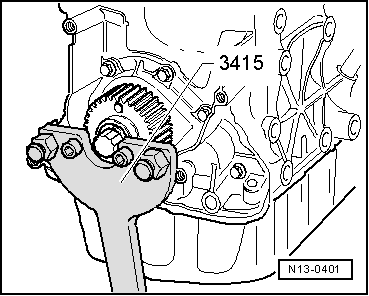

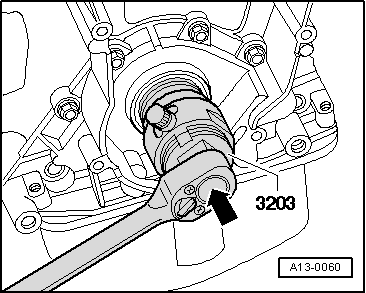

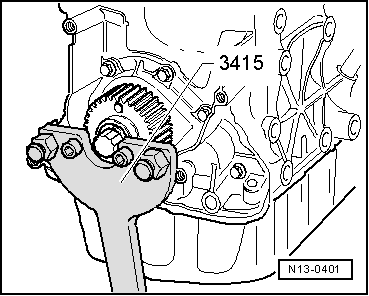

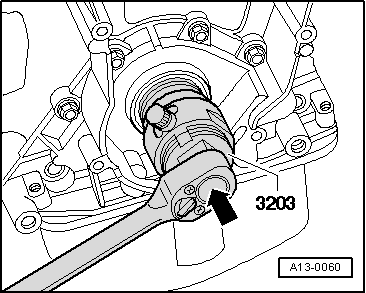

| Lubricate threaded head of oil seal extractor -3203-, place in position and exerting firm pressure, screw it as far as possible into oil seal. |

| –

| Loosen knurled screw and turn inner part against crankshaft until the oil seal is pulled out. |

Note! | Gradual introduction of PTFE seals (polytetrafluoroethylene) Characteristics: no coil spring, wider sealing lip. The sealing lip of this oil seal must not be additionally oiled or greased. A older design radial shaft seal (with coil spring) may be replaced by a PTFE seal, but not the other way around. |

| –

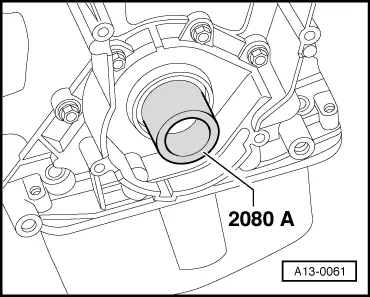

| Remove oil residue from crankshaft journal using a clean cloth. |

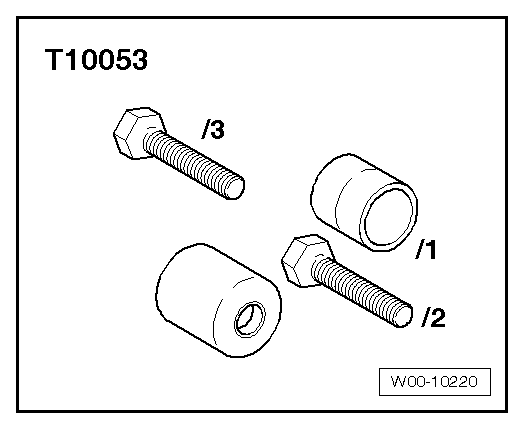

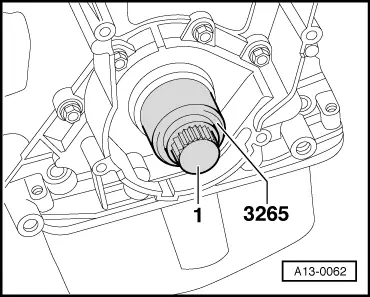

| Installing oil seal with coil spring |

| –

| Lightly oil sealing lip of oil seal. |

|

|

|

Note!

Note!

Note!

Note!