Leon Mk1

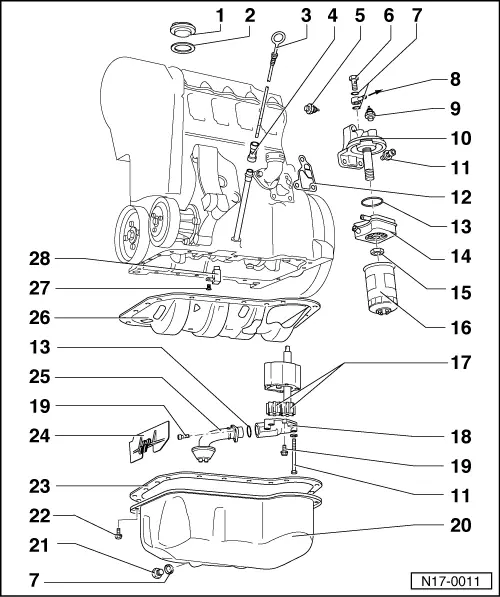

| Assembly diagram |

| 1 - | Cover |

| 2 - | Gasket |

| q | Replace if damaged |

| 3 - | Dipstick |

| q | Verification → Fig. |

| 4 - | Dipstick tube |

| q | Remove this for siphoning the oil |

| 5 - | Oil pressure switch -F22-, 25 Nm |

| q | 0.3 bar switch |

| q | Brown colour |

| q | Verification → Chapter |

| q | If the sealing ring is leaking, nip open and replace the o-ring |

| 6 - | Seal bolt, 25 Nm |

| q | For other engine identification letters |

| 7 - | O-ring |

| q | Replacement |

| 8 - | To the turbocompressor from the exhaust gases |

| q | For other engine identification letters |

| 9 - | Oil pressure switch -F1-, 25 Nm |

| q | 0.9 bar switch |

| q | Grey |

| q | Yellow cable |

| q | Verification → Chapter |

| q | If the sealing ring is leaking, nip open and replace the o-ring |

| 10 - | Oil filter bracket |

| 11 - | 25 Nm |

| 12 - | Gasket |

| q | Replacement |

| 13 - | O-ring |

| q | Replacement |

| 14 - | Oil cooler |

| q | To remove, first take away the oil filter → Item |

| q | Lubricate the contact surfaces with the oil filter support outside of the join ring using -AMV 188 100 02- |

| q | Ensure that there is enough space to the outer components |

| 15 - | 25 Nm |

| 16 - | Oil filter |

| q | For separation, use the oil filter spanner -U-30043- |

| q | Follow the fitting instructions printed on the filter |

| q | For fitting, tighten by hand |

| 17 - | Oil pump pinions |

| q | Removing |

| – | Remove the oil sump → Item |

| – | Remove the bolts → Item attaching the oil pump |

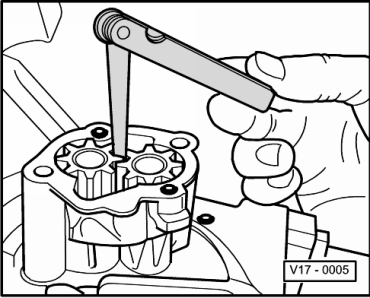

| q | Check the play between gear teeth flanks → Fig. |

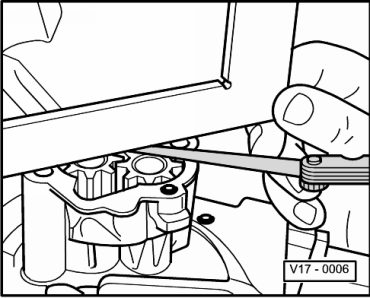

| q | Check axial play → Fig. |

| 18 - | Oil pump cover |

| q | Opening pressure: 5.7 ... 6.7 bar |

| q | Pressure regulator valve included |

| 19 - | 10 Nm |

| 20 - | Sump |

| q | Removing |

| – | Removing the sound proofing tray: → Rep. Gr.50 |

| – | Remove the lower clutch housing protection |

| – | Remove the bolts attaching the sump to the gearbox using the -U-40051A- or -U-40051+/1+/2- tool |

| – | Remove the bolts → Item |

| q | Clean sealing surface before installing |

| 21 - | Oil purge bolt, 30 Nm |

| 22 - | 20 Nm |

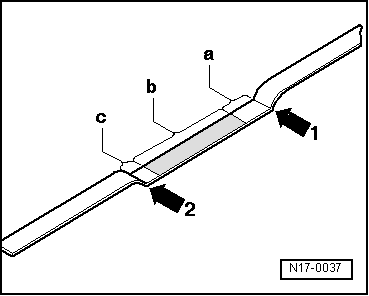

| 23 - | Oil sump gasket |

| q | For other engine identification letters |

| q | Replacement |

| 24 - | Baffle plate |

| q | Removing |

| – | Remove the oil sump → Item |

| – | Remove the suction pipe → Item |

| 25 - | Suction pipe |

| q | Clean filter if soiled |

| 26 - | Baffle plate |

| q | With gasket |

| q | Replace the gasket if it is deteriorated |

| 27 - | 10 Nm |

| q | Fit using -AMV 188 100 02- |

| 28 - | Oil injector |

| q | For piston cooling |

|

|

|

|