| Installation is carried out in the reverse order to removal, observing the following: |

Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| All conduits (for example for fuel, hydraulics, carbon filter, liquid cooler and cooling agent, brake fluid, low pressure) and the electric cables must be placed in such a way that they return to their original position. |

| Ensure sufficient clearance for all moving or hot components. |

|

| Vehicles with manual gearbox |

| –

| Check wear to the clutch release bearing and replace if necessary. |

| Vehicles with automatic gearbox |

| Continued for all vehicles |

| –

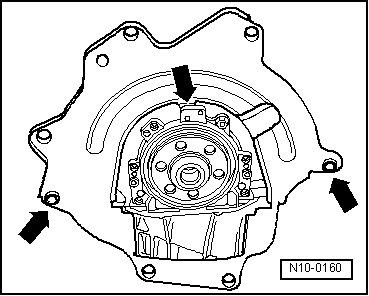

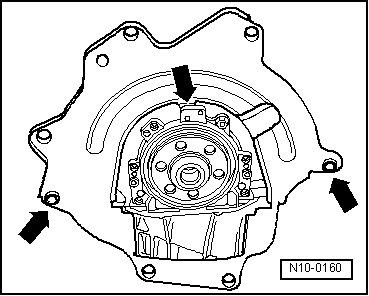

| Check whether the dowel sleeves for centring engine/gearbox are in the cylinder block, install if necessary. |

|

|

|