| l

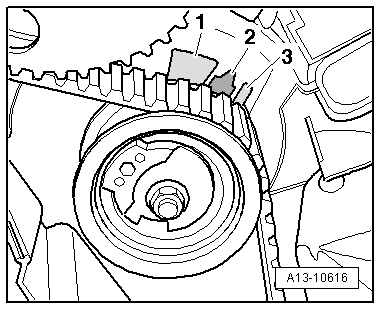

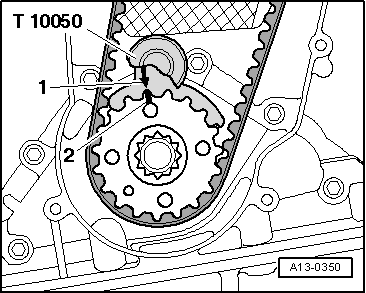

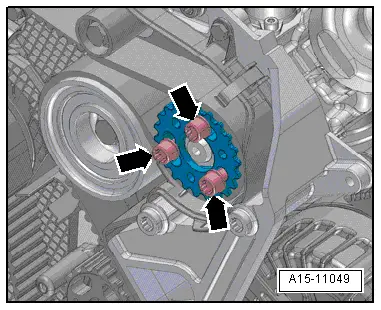

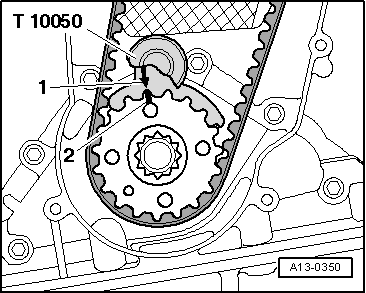

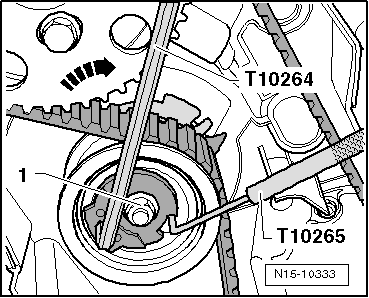

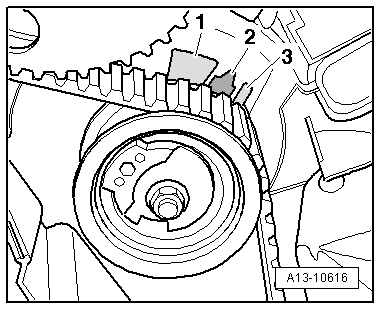

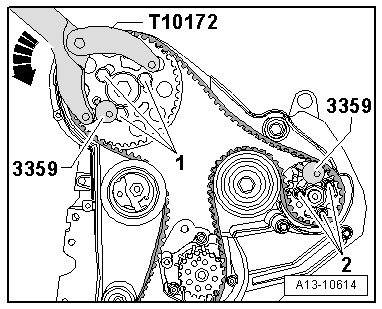

| Pointer -2- on tensioner roller must be centred between tabs -1- and -3- on base plate. |

Note | The maximum permissible sideways deviation from the specified position is 5 mm. |

| t

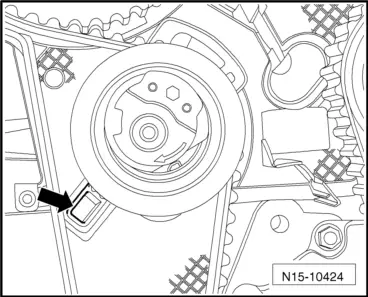

| Re-adjust valve timing if requirements are not met → Anchor. |

| t

| If requirements are met, continue with procedure after adjusting valve timing correctly as described below → Anchor. |

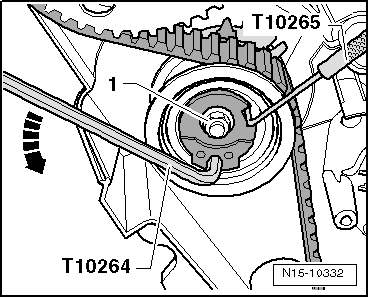

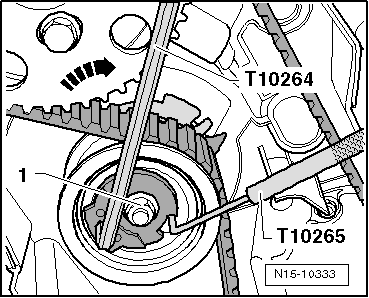

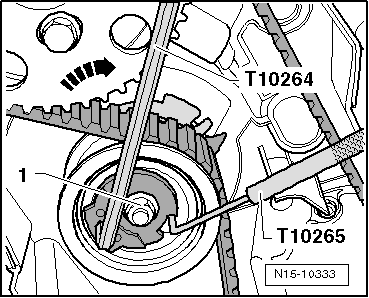

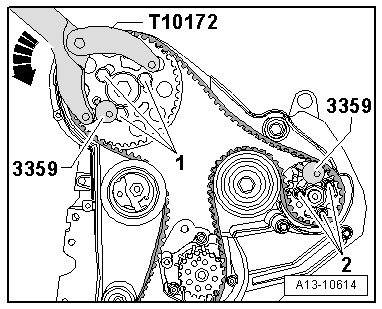

| Re-adjusting valve timing: |

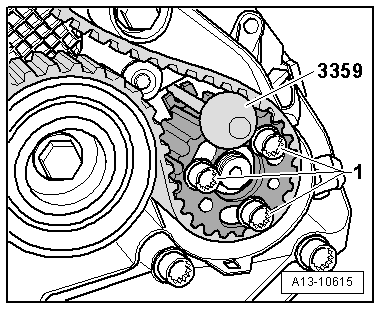

| If hub on camshaft cannot be locked: |

| –

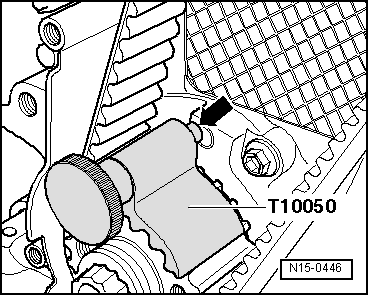

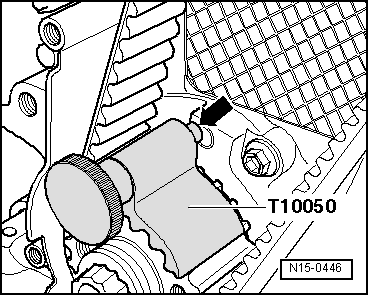

| Move the crankshaft stop -T10050- back until the journal releases the opening. |

| –

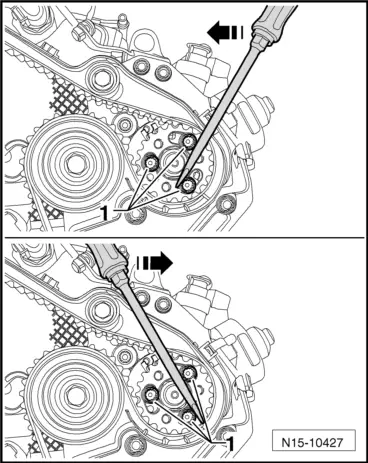

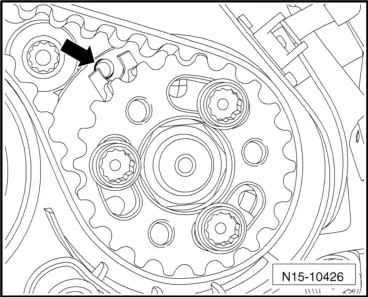

| Turn crankshaft in opposite direction of engine rotation slightly past „TDC“. |

| –

| Now turn crankshaft slowly in direction of engine rotation until camshaft hub can be secured in position. |

| –

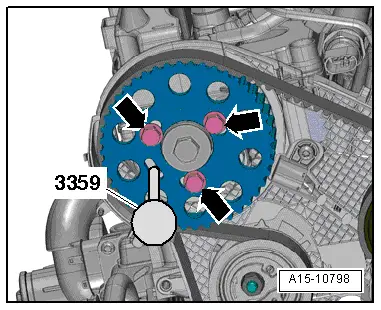

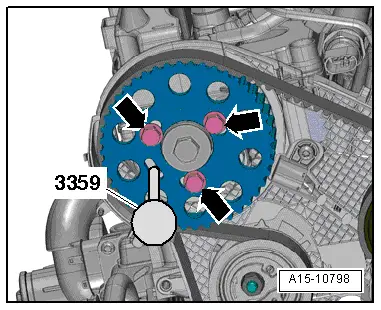

| After locking, loosen securing nuts of crankshaft toothed belt pulley. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution