| t

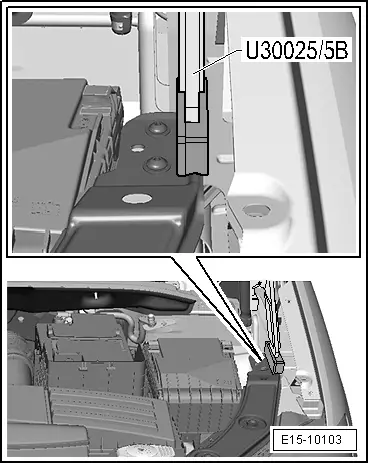

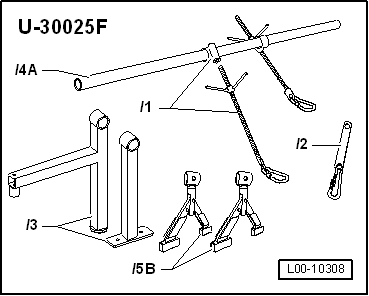

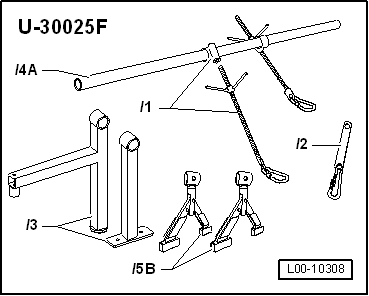

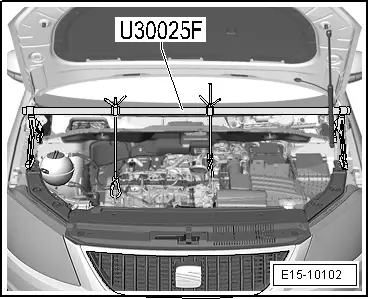

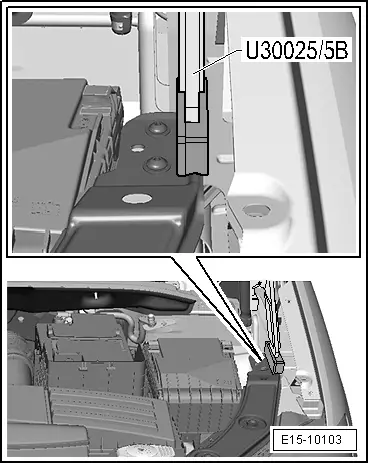

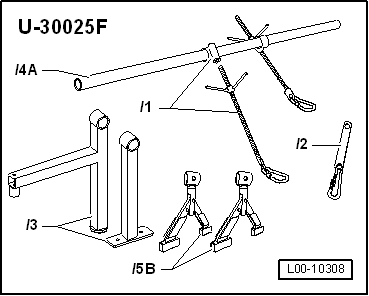

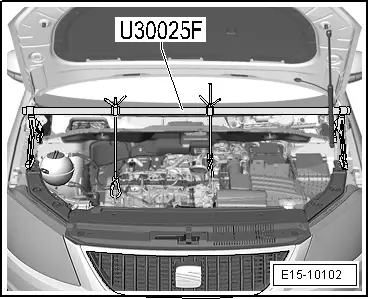

| Support bracket -U-30025F- |

| t

| Torque wrench -V.A.G 1331- |

| t

| Spring-type clip pliers -VAS 6362- |

WARNING | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route lines of any kind so that the original routing can be restored. |

| t

| Ensure that there is sufficient clearance to all moving or hot components. |

|

| –

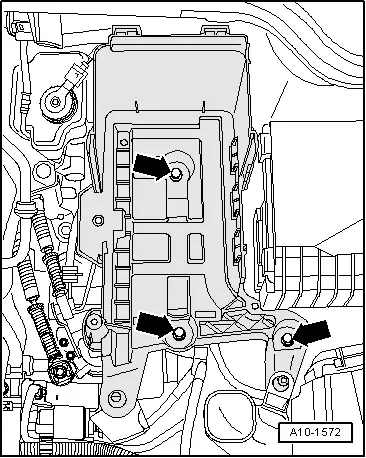

| Remove intake hose between air mass meter -G70- and intake connecting pipe. |

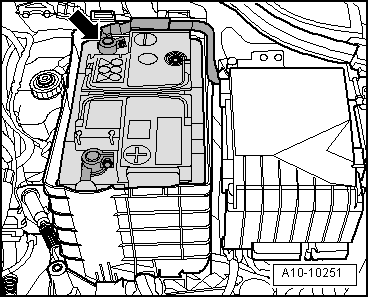

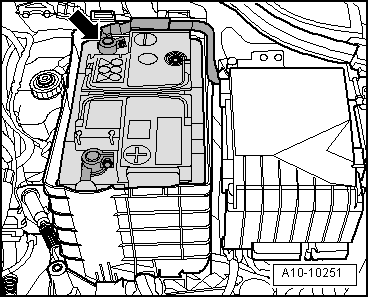

Caution | To prevent damage to the electronic components when disconnecting the battery: |

| Observe notes on procedure for disconnecting the battery. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note