| –

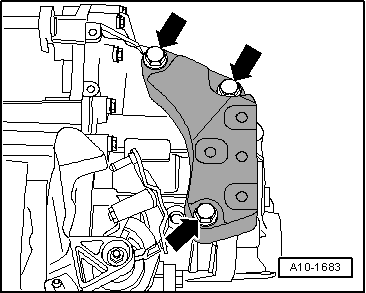

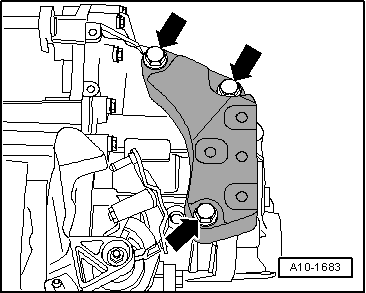

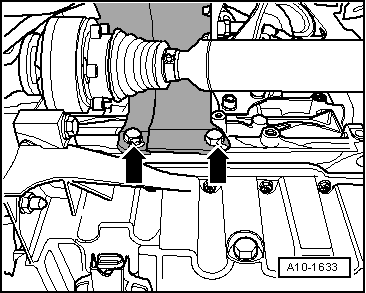

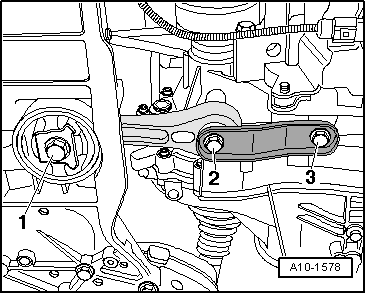

| Mount the gearbox support and tighten the bolts -arrows- to 60 Nm + 90° (1/4 rotations). |

| –

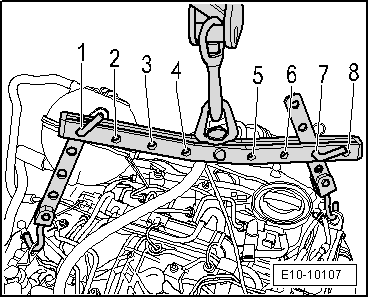

| When installing the »engine assembly«, take care that sufficient free is at hand to the engine assembly. |

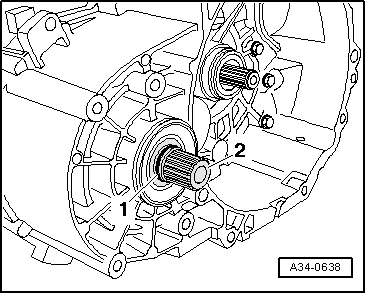

| Four wheel drive vehicles |

| All vehicles (continued): |

| –

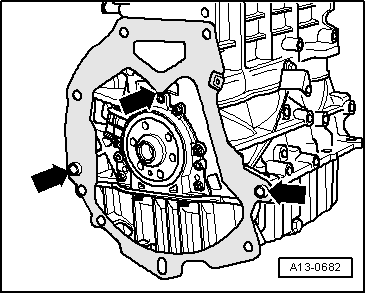

| Insert the engine/gearbox assembly into the body. |

Note | t

| When fitting the engine assembly, continue with care so that the bodywork is not damaged. |

| t

| After working on the particulate filter, ensure it is installed free of stress. |

| t

| Renew self-locking nuts, seals, gaskets and securing clamps. |

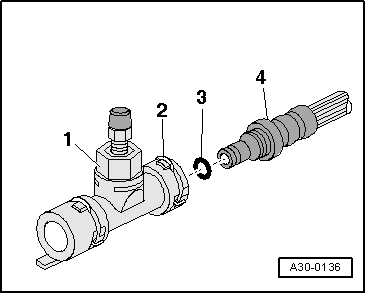

Caution | Avoid damage of decoupling element behind particulate filter. When removing and installing: |

| t

| Do not bend decoupling element more than 10°. Secure with transportation lock -T10404-. |

| t

| Install decoupling element so that it is not under tension. |

| t

| Take care not to damage wire mesh on decoupling element. |

|

| –

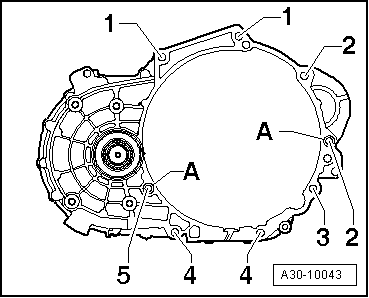

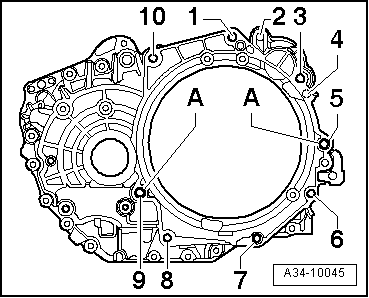

| Fit the bearing of the engine assembly, engine and gearbox side. |

Note | Specified torques for assembly mountings → Chapter |

| –

| Hang-out and remove the workshop crane -VAS 6100- and remove the suspension device -2024A- of the engine. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Caution

Caution WARNING

WARNING