| –

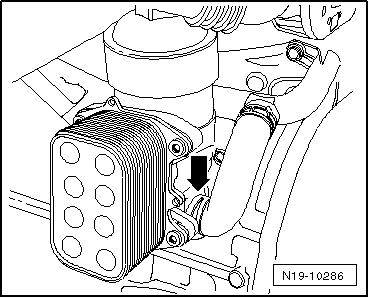

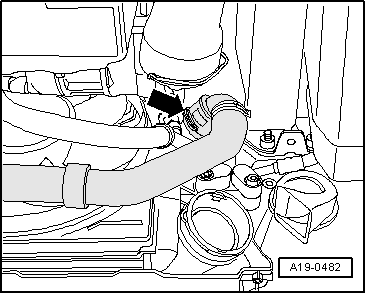

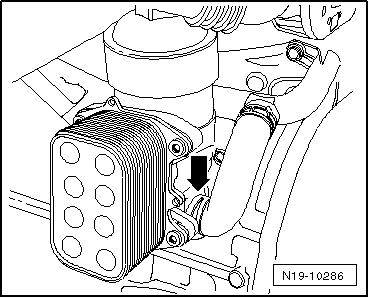

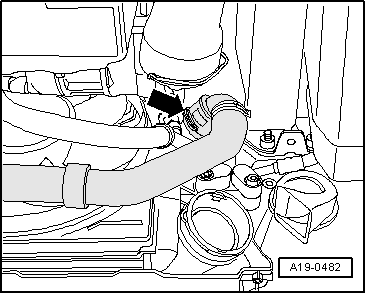

| To drain coolant from engine also remove coolant hose from oil cooler -arrow-. |

Note | Please observe requirements for disposal. |

Note | The amount of water used in the coolant mixture has a great influence on its effectiveness. With respect to the contents that may vary from country to country, or even region to region, Volkswagen has made the decision to define the quality of the water that is used for the cooling system. Distilled water fulfils all requirements. It is therefore recommended that distilled water be mixed with the coolant whenever an older model's coolant is replenished or replaced. The use of purified water is mandatory for the newest models (year of manufacture 2010 ►). |

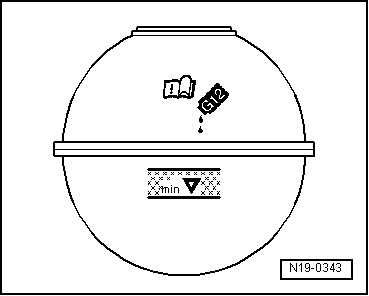

Caution | Only distilled water may be mixed with G12 plus-plus. The use of distilled water ensures optimum protection against corrosion. |

|

Note | t

| Only use antifreeze additive G 12 plus-plus according to specification TL VW 774 G. |

| t

| It is only permissible to use distilled water for mixing. |

| t

| „TLºVWº774ºG“ or „TLºVWº774ºF“ anti-freeze agents prevent damage from rust, freezing or lime sediment, and also raise the boiling point of the coolant. For these reasons, the cooling system must be filled all year round with an anti-freeze and anti-corrosion agent. |

| t

| In countries with a tropical climate, the cooling liquid increases the boiling point and guarantees secure operation when the engine is put under strain. |

| t

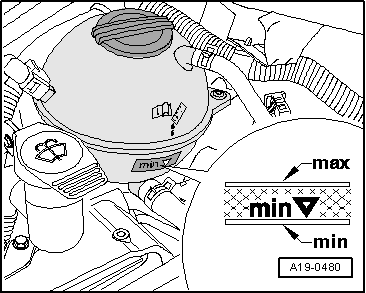

| Frost protection must be assured to about -25 °C (in arctic climatic countries to about -35 ℃). |

| t

| During hotter seasons of the year and in hot countries, the coolant concentration should not be reduced by adding only water. The amount of anti-freeze in the coolant must be at least 40 %. |

| t

| If for climatic reasons it is necessary to increase the coolant protection, you may raise the proportion of the antifreeze agent and anti-corrosive, but without exceeding 60% (antifreeze protection up to -40 ºC), from this proportion the antifreeze protection is diminished, aside from reducing the coolant capacity. |

| t

| If radiator, heat exchanger, cylinder head or cylinder head gasket has been replaced, do not reuse old coolant. |

| t

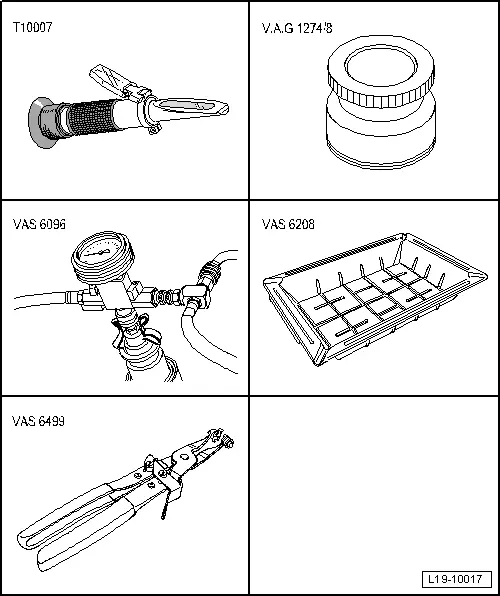

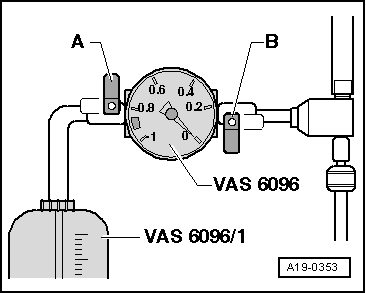

| For checking anti-freeze protection in cooling system, use refractometer -T10007-. |

| t

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

| Recommended mixture ratios: |

|

|

|

Note

Note

Note

Note Note

Note Note

Note

WARNING

WARNING Caution

Caution