| –

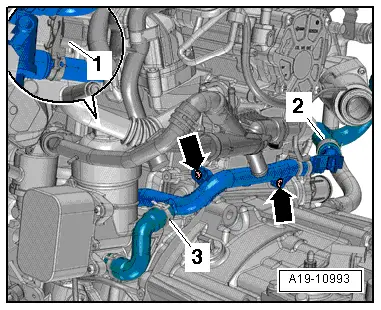

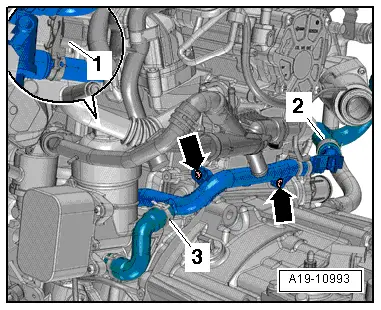

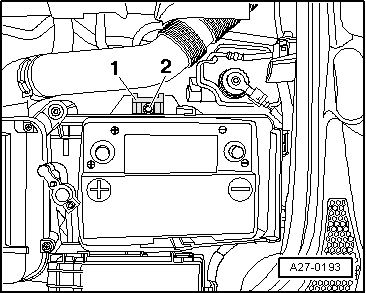

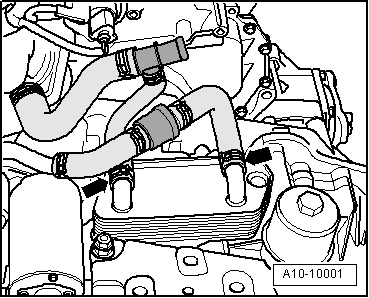

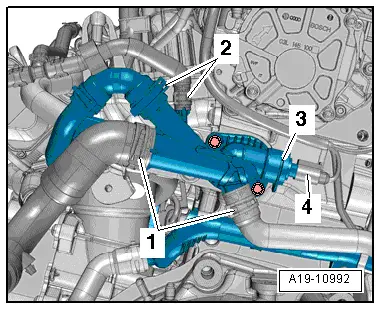

| Release hose clips -2- and -3-, and pull coolant hoses off. |

| –

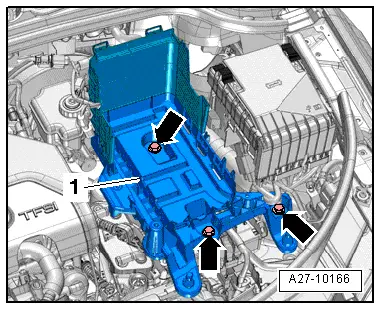

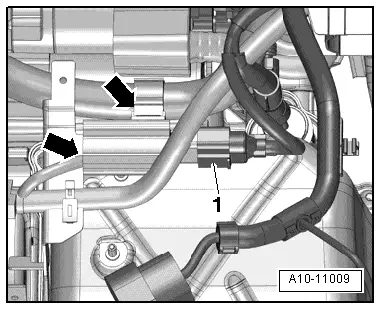

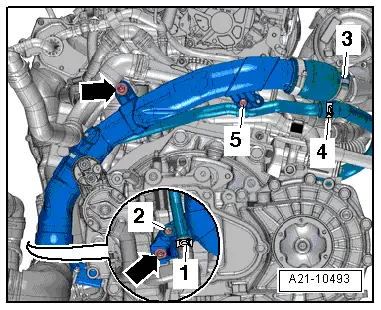

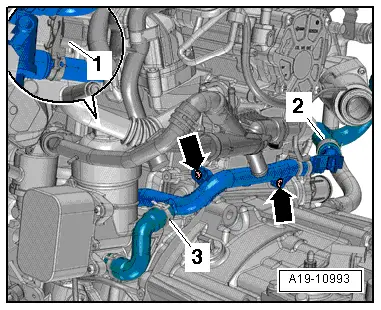

| Unscrew bolts -arrows- and pull front coolant pipe out of 4/2-way valve. |

| Installation is carried out in reverse sequence; note the following: |

Note | t

| Renew gaskets, seals and O-rings. |

| t

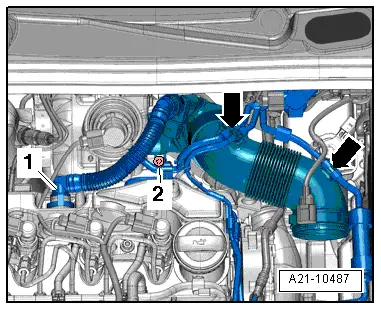

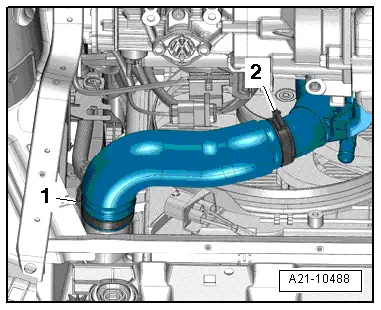

| Hose connections and air pipes and hoses must be free from oil and grease before fitting. |

| –

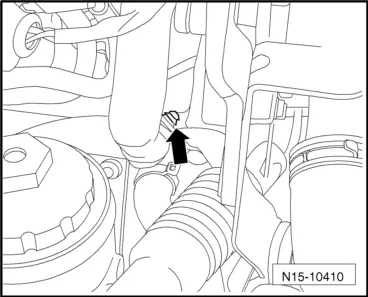

| Clean or smoothen sealing surface for O-ring. |

| –

| Moisten O-ring with coolant and slide onto front coolant pipe. |

| –

| Push front coolant pipe into 4/2-way valve. |

| –

| Fill coolant system with coolant → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note