Leon Mk1

|

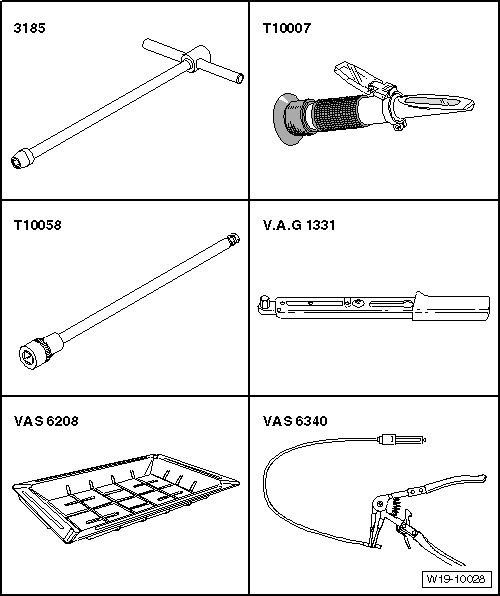

| Special tools and workshop equipment required |

| t | Articulated wrench e/c 10 -VAS 3185-, see equivalent → Anchor |

| t | Refractometer -T10007-, see equivalent → Anchor |

| t | Spanner -T10058-, see equivalent → Anchor |

| t | Torque wrench (5 - 50 Nm) -V.A.G 1331-, see equivalent → Anchor |

| t | Collector tray for workshop crane -VAS 6208-, see equivalent → Anchor |

| t | Base -VAS 6340-, see equivalent → Anchor |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING