Leon Mk1

| Renewing valve stem seals with cylinder head removed |

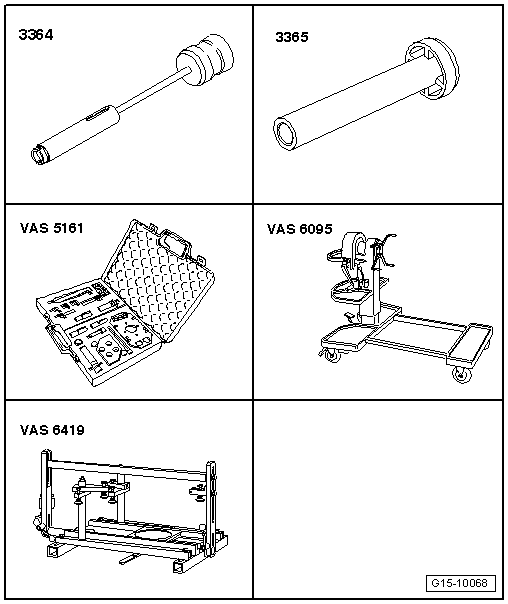

| Special tools and workshop equipment required |

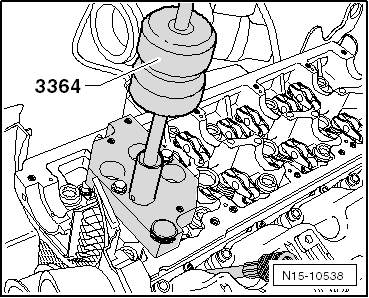

| t | Valve stem seal puller -3364- |

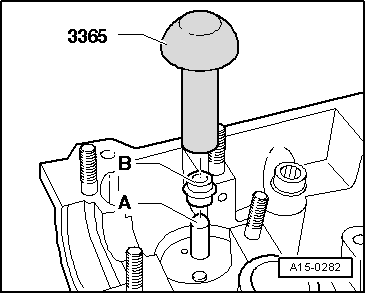

| t | Valve stem seal fitting tool -3365- |

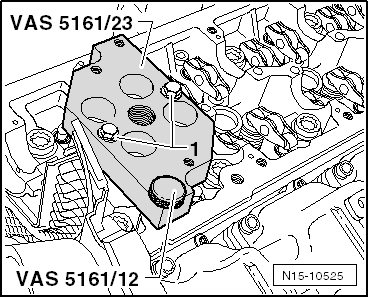

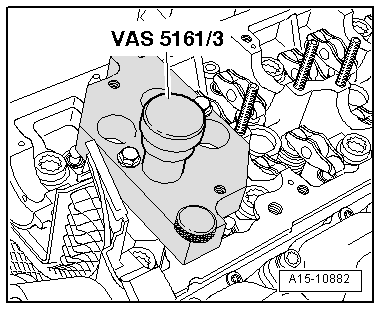

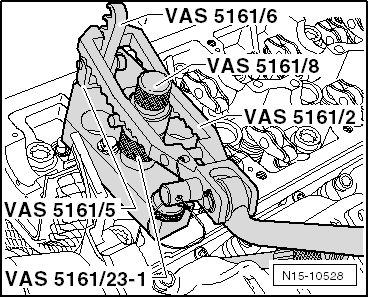

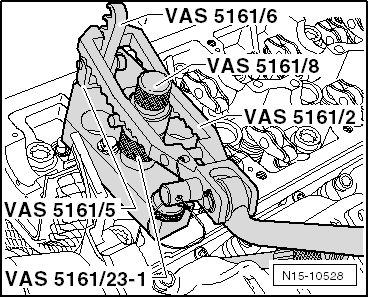

| t | Removal and installation device for valve cotters -VAS 5161- with guide plate -VAS 5161/23- and sleeve -VAS 5161/23-1- |

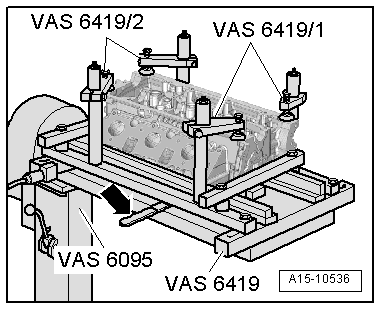

| t | Engine and gearbox support -VAS 6095- |

| t | Cylinder head tensioning device -VAS 6419- |

| t | 2x M6x30 bolts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution