Leon Mk1

|

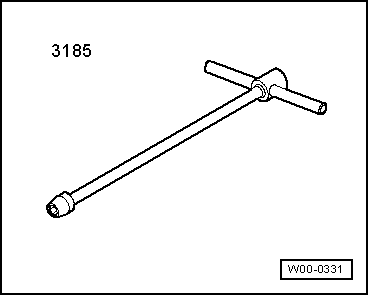

| Special tools and workshop equipment required |

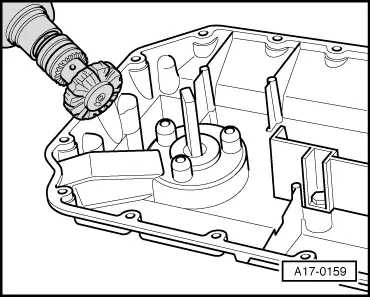

| t | Extractor -SAT 1100-, see equivalent → Anchor |

| t | Spanner -T10058-, see equivalent → Anchor |

| t | Torque wrench (5 - 50 Nm) -V.A.G 1331-, see equivalent → Anchor |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

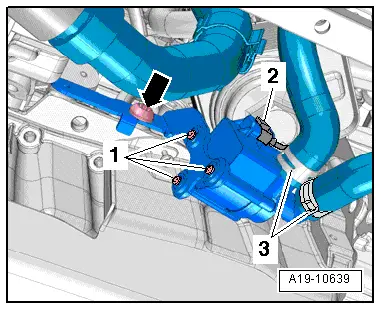

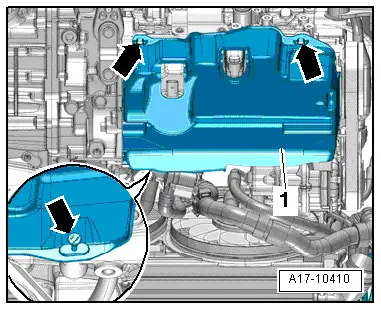

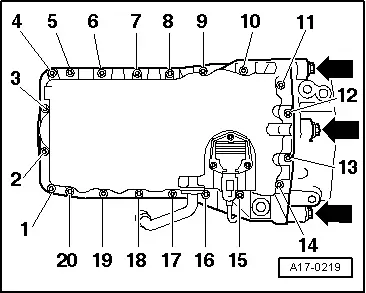

| stage: | Bolts | Specified torque |

| 1. | -1 … 20- | diagonally, 5 Nm |

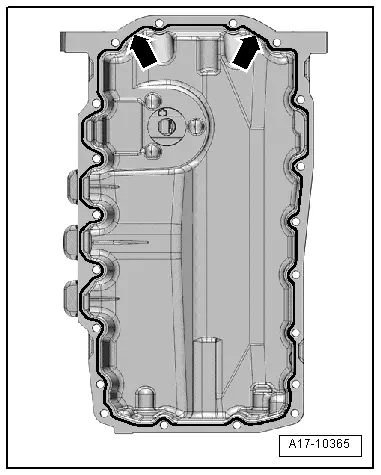

| 2. | -arrows- | 40 Nm |

| 3. | -1 … 20- | in diagonal sequence, in stages and finally to 15 Nm |

Note

Note

|

|

|

Caution

Caution WARNING

WARNING