| l

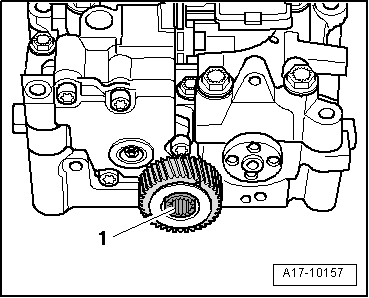

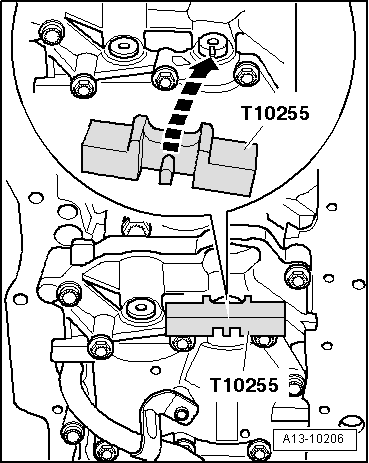

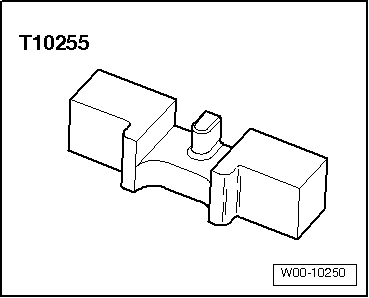

| Crankshaft locked in position with crankshaft stop -T10050-. |

Note | t

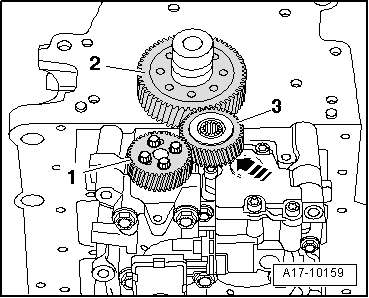

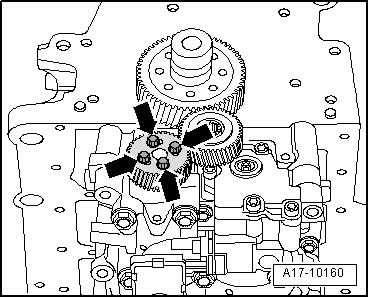

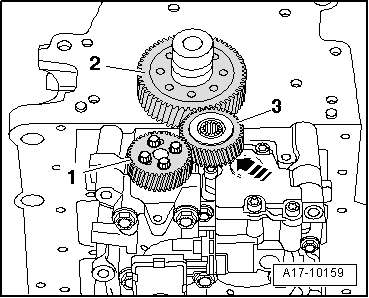

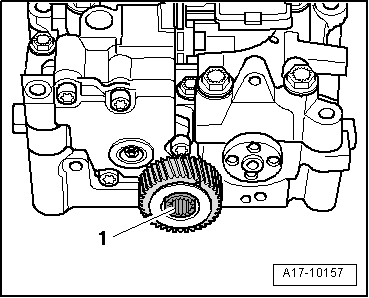

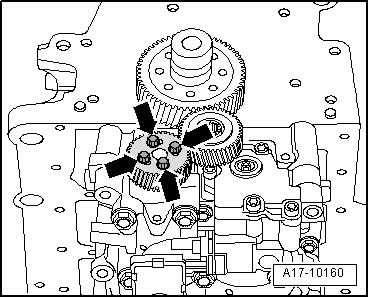

| The drive spur of the balancer shaft module must with a tooth backlash of 0.038 ... 0.072 mm. |

| t

| A coating of correct thickness is applied to the new intermediate gear wheel to set the correct backlash. The coating is applied in part around the teeth. |

| t

| The coating is quickly worn away, which sets the correct backlash. |

| t

| A new balancer shaft module must always be installed with a new intermediate gear wheel with coating. |

| t

| Renew bolts tightened through an additional specified angle. |

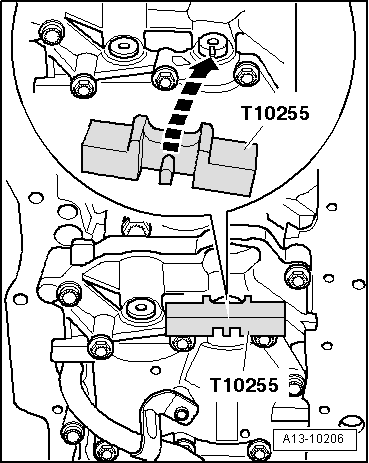

Caution | Risk of thrust washer slipping behind intermediate gear wheel. |

| To fit balancer shaft module, do not loosen intermediate gear wheel bolt more than specified. Thrust washer installation position → Fig. |

|

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note