Leon Mk1

|

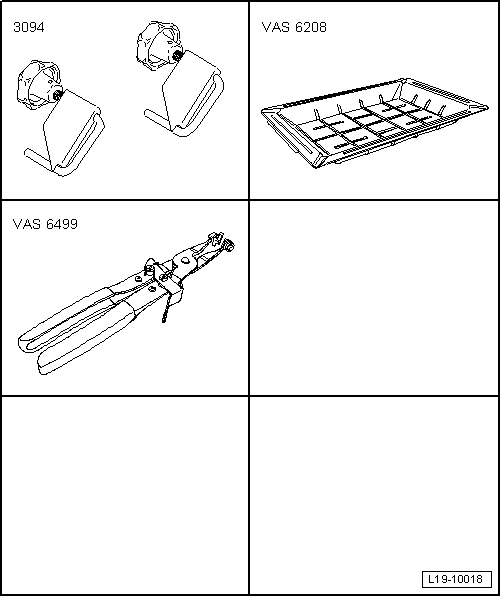

| Special tools and workshop equipment required |

| t | Hose clamps -3094-, see equivalent → Anchor |

| t | Collecting tray -VAS 6208-, see equivalent → Anchor |

| t | Base -VAS 6499-, see equivalent → Anchor |

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|