| t

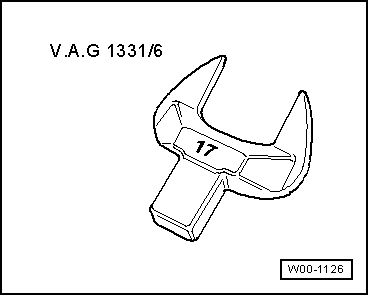

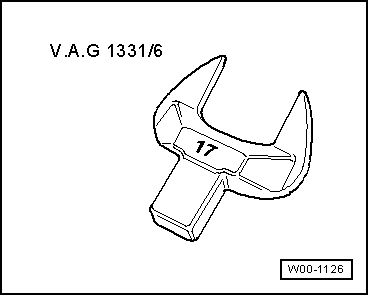

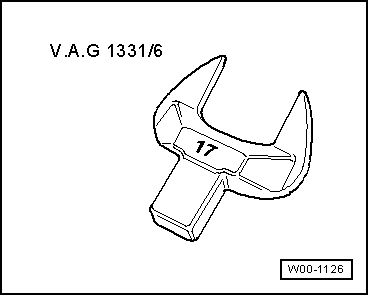

| Pin tool e/c 17 -V.A.G 1331/6-, see equivalent → Anchor |

| t

| Screw plug -T40204-, see equivalent → Anchor |

WARNING | t

| When carrying out work on the fuel system, always observe the guidelines for cleanliness and the instructions → Chapter. |

| t

| Follow these instructions and rules for cleanliness before starting work and while working on the fuel system. |

|

| –

| Event memory entry using the vehicle diagnosis tester. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note