| –

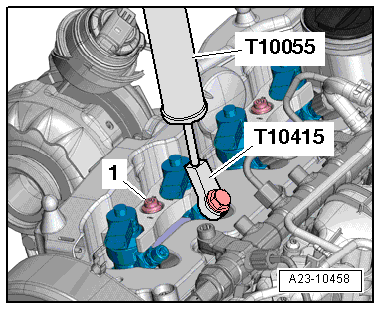

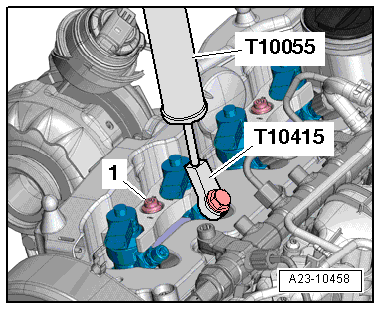

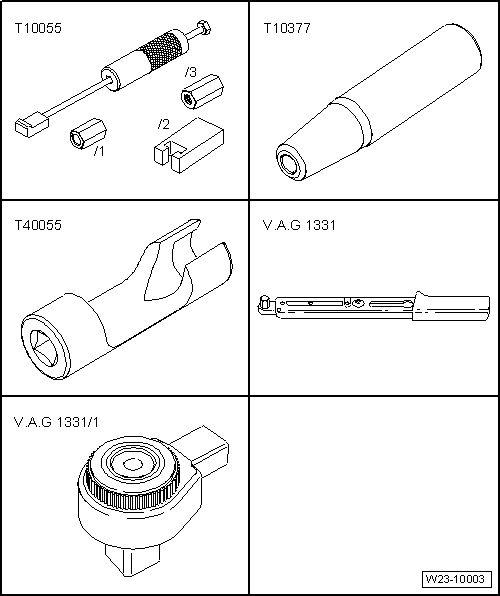

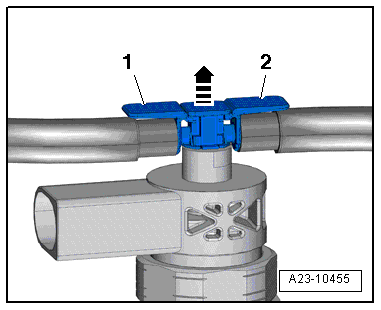

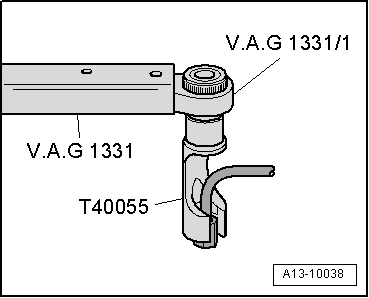

| Set the extractor -T10055- with the Adapter -T10415- and pull out the injector upwards with light knocking motions. |

Note | Pull injector out using rotary movements in order not to damage sealing lip. |

| –

| After removal, lay injectors on a clean cloth. |

| Important instructions for installing injectors: |

| l

| The following components and seals or O-rings must be replaced after each installation or removal: „Copper washer“„O-ring of the injector valve adapter shaft“ and „O-ring on the injector valve return connection“. |

| l

| The following components and seals or O-rings must always be replaced when an injector is renewed: „Clamping piece“, „Copper washer“, „O-ring from the injector bore“, „O-ring from the injector valve return connection“ |

| l

| Lubricate all O-rings with engine oil or assembly oil before installing. |

Note | t

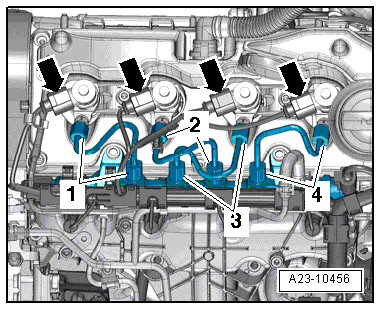

| Observe cylinder specific markings when reusing high-pressure lines. |

| t

| The high-pressure pipes can be re-used after performing the following checks: |

| t

| Check sealing cone on corresponding high pressure line for deformation and cracks. |

| t

| The inside of the line must not show any signs of deformation, changes or damage. |

| t

| Rusty lines must not be used again. |

| If a used injector is being re-installed: |

| –

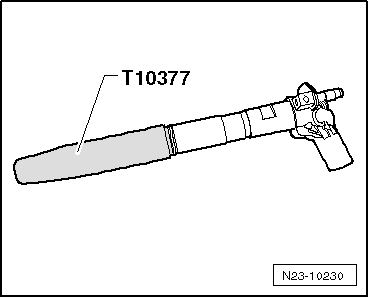

| Spray tip of injector nozzle with rust-releasing spray. Wait approx. 5 minutes and wipe off soot particles and oil with a cloth. |

| –

| With severe contamination of an injector additionally the tip of the injector unit must be cleaned with a soft brass brush, so that the copper sealing ring can be lightly removed (no scratches should occur due to the brush on the jets of the injectors). |

| –

| To remove the old copper seal from the injector, clamp the seal carefully in a vice so that it is just held between the jaws without turning. Then carefully pull and twist the injector out of the copper seal by hand. |

| –

| Clean off deposits under the copper seal using a suitable scraper. |

Caution | To remove carbon deposits from the injector sealing surface, clean the injector seat in the cylinder head with a cloth soaked in engine oil or rust solvent. Take care not to damage the sealing surface. |

|

|

|

|

Note

Note Note

Note Note

Note

WARNING

WARNING Caution

Caution