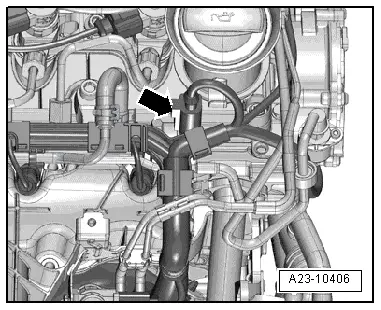

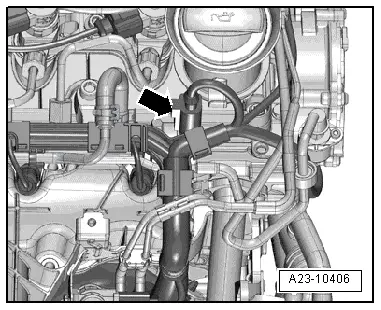

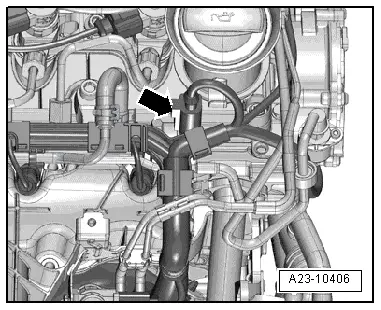

| Fuel pressure regulating valve -N276--2- is located in fuel rail. It maintains constant pressure in fuel rail and injection lines (fuel high-pressure circuit). |

| If the pressure in the fuel high-pressure circuit is too high, the regulating valve opens to allow some of the fuel to flow back from the fuel rail to the fuel tank via a return line. |

| If the pressure in the high-pressure fuel circuit is too low, the fuel pressure regulating valve -N276- closes and seals off the high-pressure section of the system from the low-pressure section. |

Note | Fuel pressure regulating valve -N276- must be renewed each time after removing. |

WARNING | t

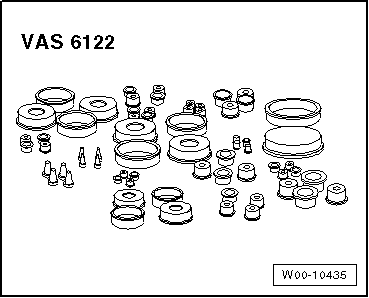

| When carrying out work on the fuel system, always observe the guidelines for cleanliness and the instructions → Chapter. |

| t

| Follow these instructions and rules for cleanliness before starting work and while working on the fuel system. |

|

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note