Leon Mk1

| Removing and installing camshaft timing chain |

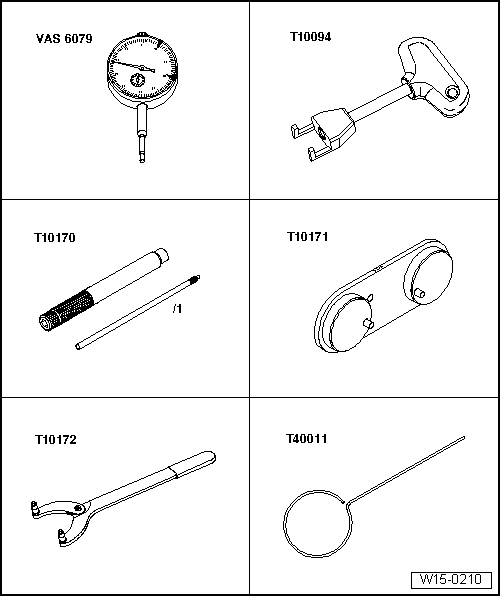

| Special tools and workshop equipment required |

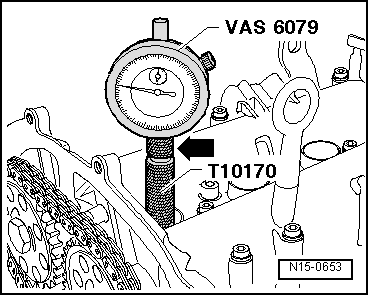

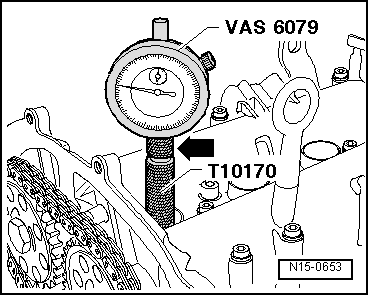

| t | Gauge -VAS 6079-, see equivalent → Anchor |

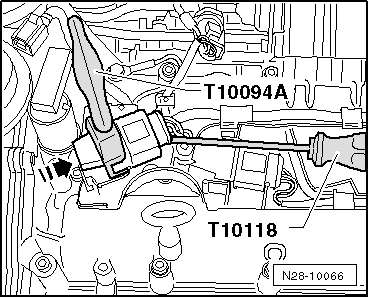

| t | Extraction tool -T10094 A-, see equivalent → Anchor |

| t | Dial gauge adaptor -T10170-, see equivalent → Anchor |

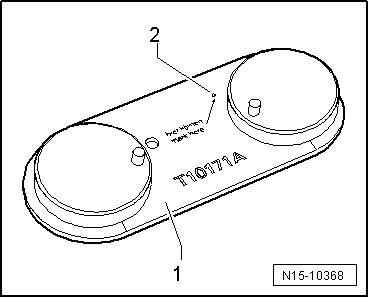

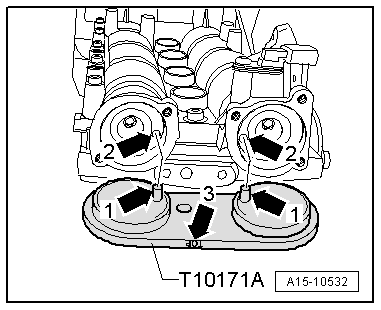

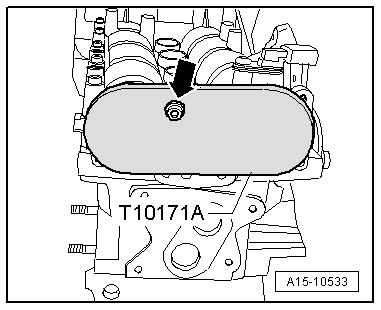

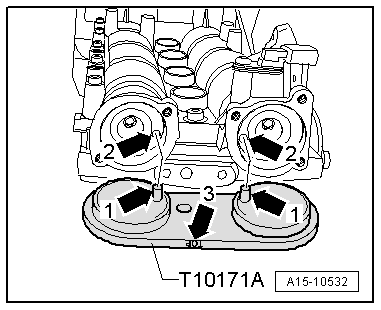

| t | Camshaft clamp -T10171 A-, see equivalent → Anchor. |

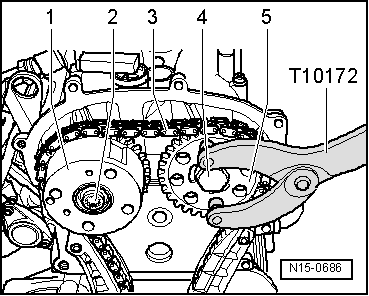

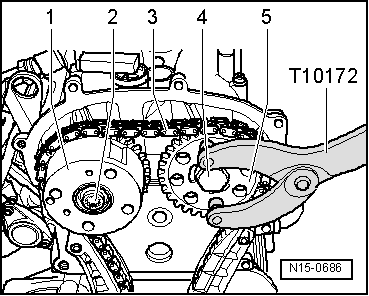

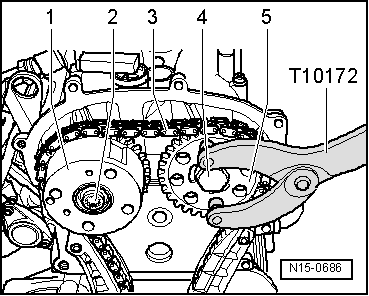

| t | Hose clamp -T10172-, see equivalent → Anchor |

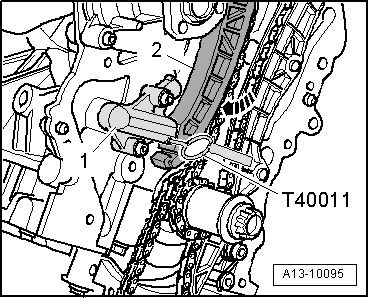

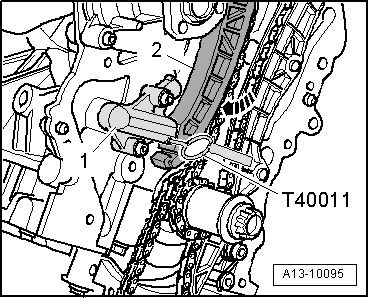

| t | Pin -T40011-, see equivalent → Anchor |

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Caution

Caution