| –

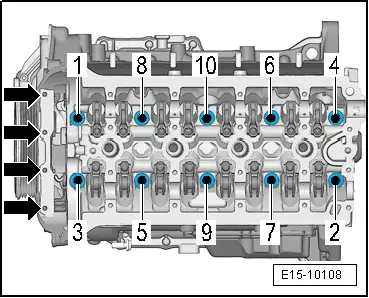

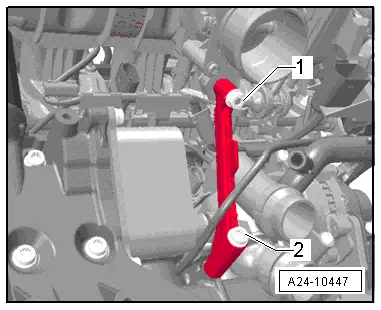

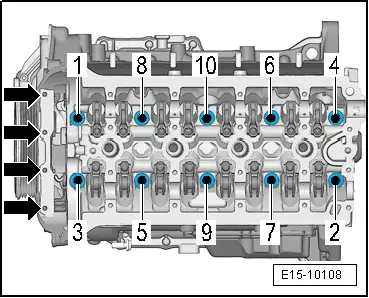

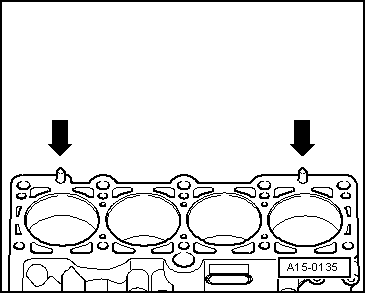

| Unscrew the bolts from the cylinder head in the sequence -1 … 10-. |

Note | t

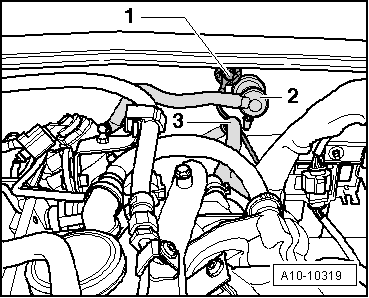

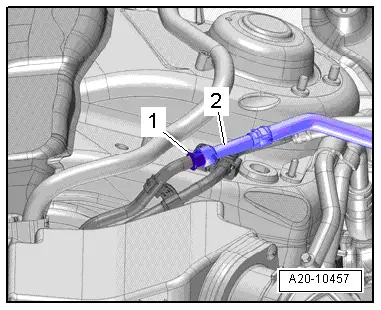

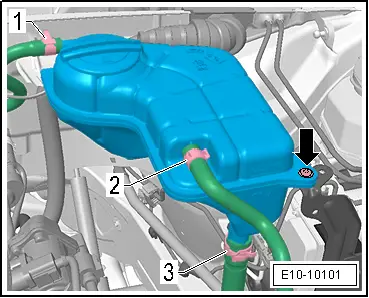

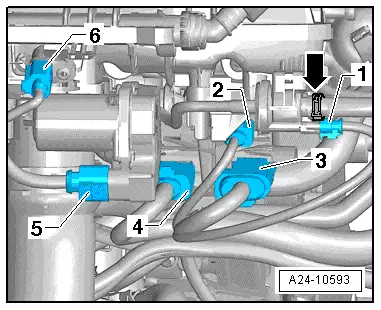

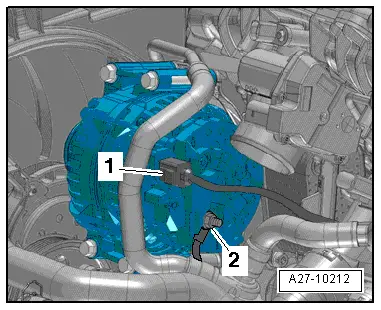

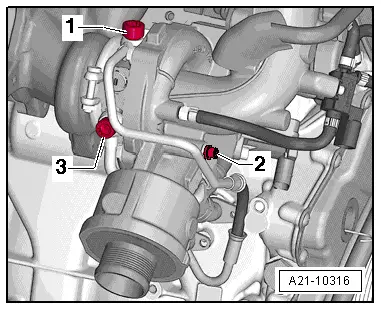

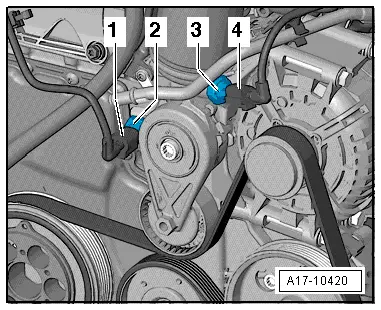

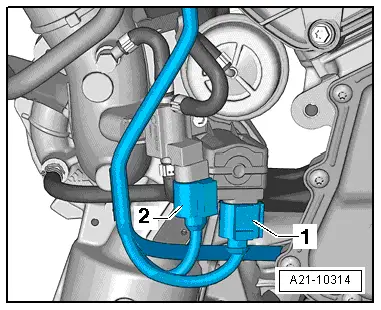

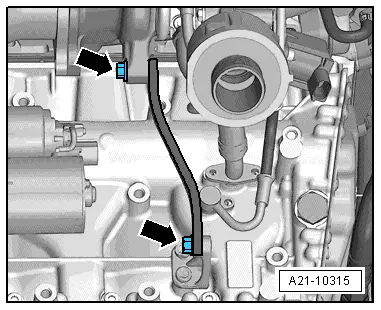

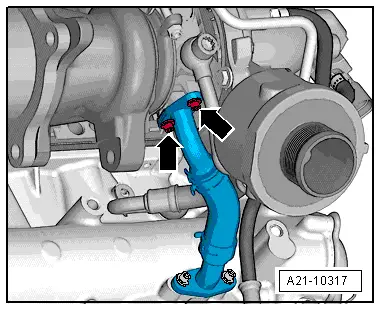

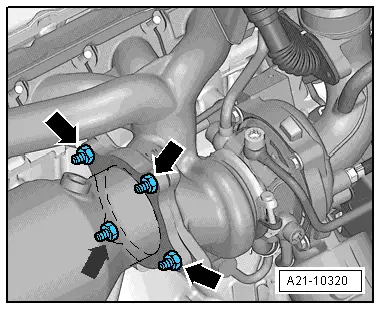

| Make sure all hoses/pipes and wiring on component are removed. |

| t

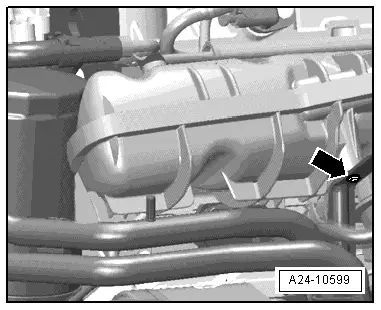

| Make sure tensioning rail and guide rail are not damaged when lifting off cylinder head. |

| –

| Remove the cylinder head. |

| –

| Place cylinder head onto soft surface (foam plastic). |

Caution | Avoid damage to sealing surfaces. |

| t

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Avoid damage to cylinder block. |

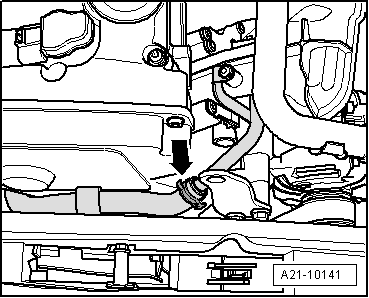

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| Ensure that cylinder head gasket seals properly: |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Avoid damage to open valves. |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| Avoid damage to valves and piston crowns after working on valve gear. |

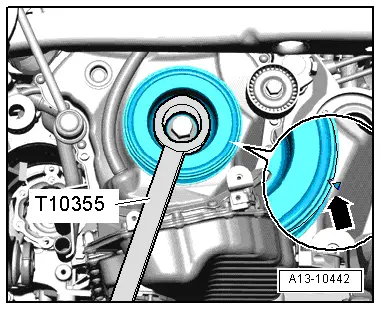

| Turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

| Renew seals, gaskets and self-locking nuts. |

| t

| Consider the different sealant types that have to be used for the sealing surface and the bolt of the cylinder head. |

| t

| When installing an exchange cylinder head, the contact surfaces between the hydraulic compensation elements, roller rocker fingers and cams must be oiled before installing the camshaft. |

| t

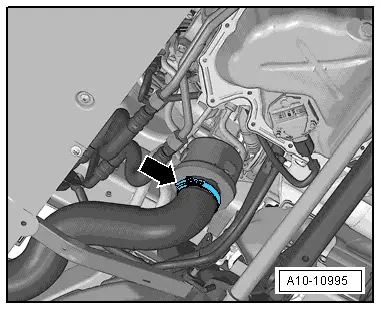

| Hose connections and air pipes and hoses must be free from oil and grease before fitting. |

| t

| To ensure that the charge air hoses can be connected securely, you must spray the screws on used screw-type clips with rust remover prior to installation. |

| t

| After fitting a new cylinder head or cylinder head gasket, change the engine oil and coolant. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution WARNING

WARNING