| –

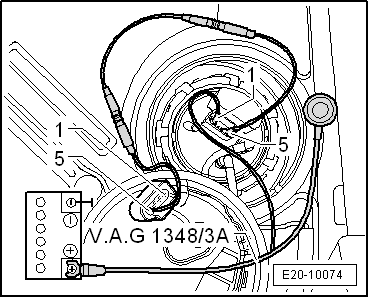

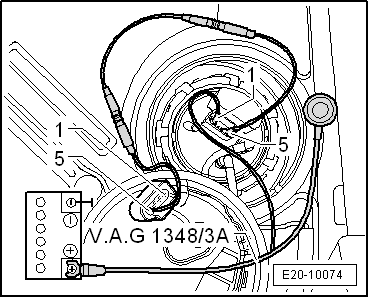

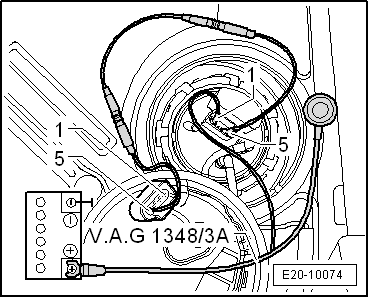

| Using the auxiliary cables of the auxiliary measuring set -VAG 1594C-, connect the remote control -V.A.G 1348/3A- to contact -1- of the fuel pump and to the positive terminal of the battery |

| –

| Using the auxiliary cables of the auxiliary measuring set -VAG 1594C-, connect the contact -5- of the plug connector to the contact -5- of the fuel pump. |

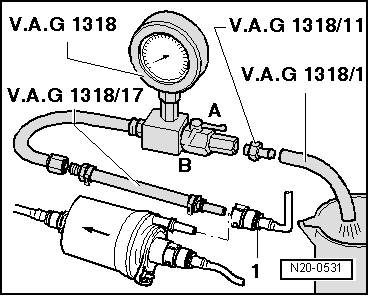

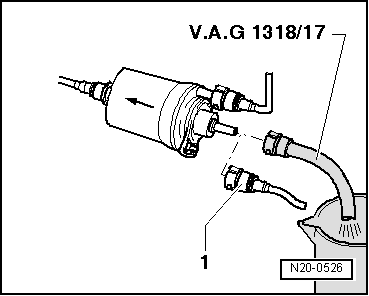

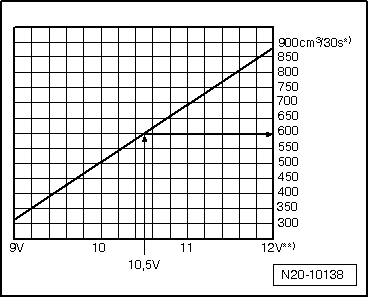

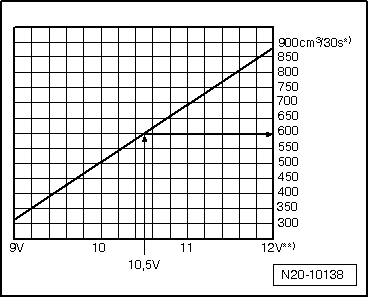

Note | The delivery rate of the fuel pump is measured at a pressure of 4 bar. This is why you have to check the fuel pressure before measuring the delivery rate. |

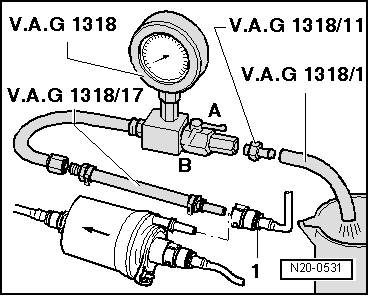

WARNING | Fuel system is under pressure! Wear safety goggles and appropriate clothing to avoid injury and contact with skin. Before loosening hose connections, wrap a cloth around the connection. Then eliminate the pressure by carefully separating the pipe. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note