| –

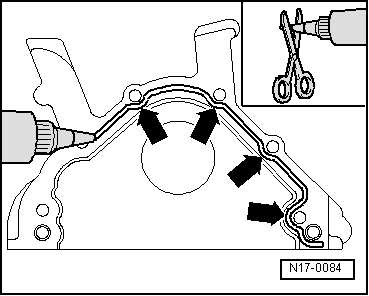

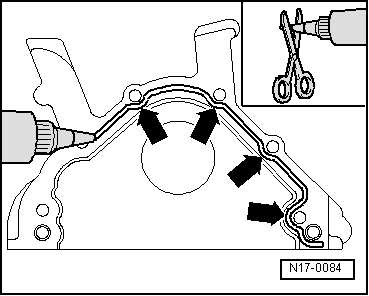

| Cut nozzle off tube at front marking (Ø nozzle diameter approx. 3 mm). |

| –

| A layer of adhesive sealing material of approximately 2-3 mm as shown in -arrow- on the clean, apply sealed surface of the sealing flange. |

Note | t

| Before applying the strip of sealant, clean the seal with a clean cloth. |

| t

| The strip of sealant must not be thicker than 2 - 3 mm, otherwise the excess sealant may enter the oil sump and obstruct the strainer in the oil intake pipe. |

| t

| Observe use-by date of sealant. |

| t

| The sealing flange must be installed within 5 minutes of applying silicone sealant. |

| t

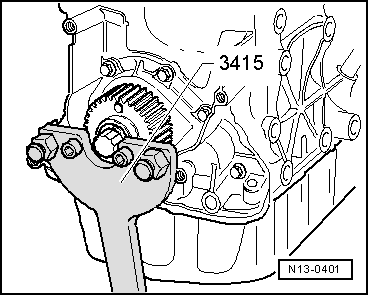

| Once the seal is installed, use the guide sleeve -T10053/1- to position the sealing flange. |

| t

| After fitting sump, allow the sealant to dry for approx. 30 minutes. Only then should the engine be refilled with oil. |

|

|

|

Note

Note

Note

Note