Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

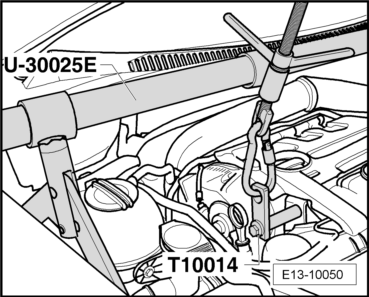

| Special tools and workshop equipment required |

| t | counterhold -T10014-, see equivalent → Anchor |

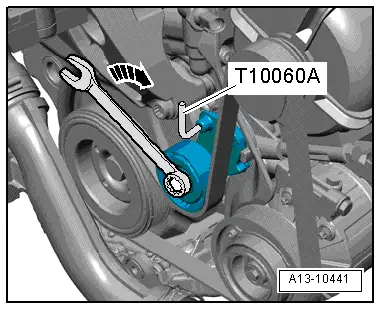

| t | Interlocking mandril -T10060 A-, see equivalent → Anchor |

| t | Bits -T10099-, see equivalent → Anchor |

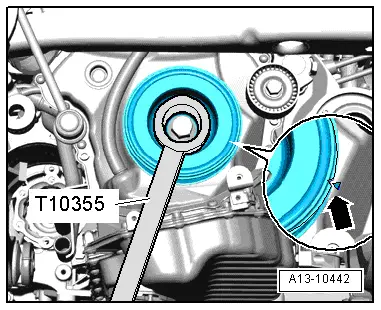

| t | Spanner -T10355-, see equivalent → Anchor |

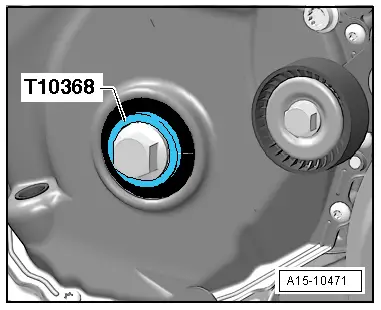

| t | Tappet -T10368-, see equivalent → Anchor |

| t | Bracket -U 30025E-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING