Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

| t | Articulated wrench e/c 10 -3185-, see equivalent → Anchor |

| t | Measuring container -T10058-, see equivalent → Anchor |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Electric drill with plastic brush attachment |

| t | Flat scraper |

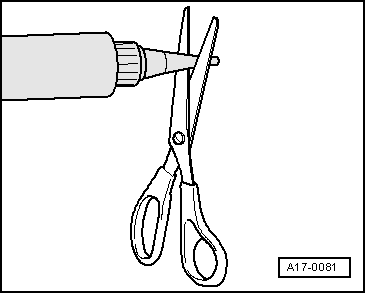

| t | Silicone sealant → Spare parts catalogue |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

WARNING

WARNING