| –

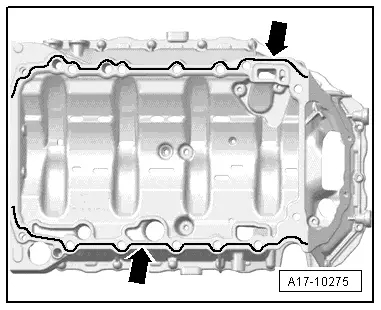

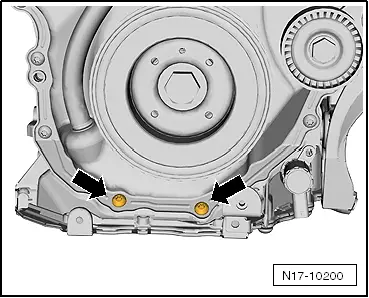

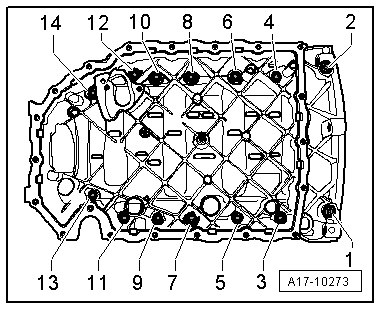

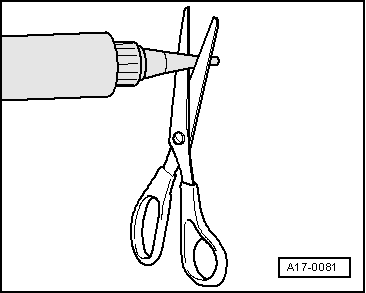

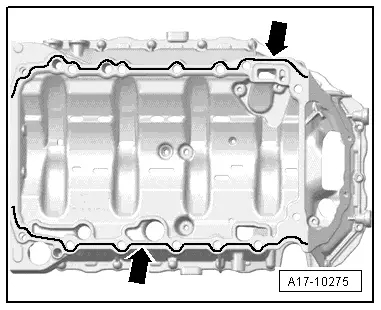

| Apply a line of silicon sealant, as shown in the figure -arrows-, to the clean sealing surface of the upper oil sump. |

| t

| Thickness of the sealant grub: 2 to 3 mm. |

Note | t

| There is a 5-minute time limit for fitting the upper part of the sump once the silicone sealant has been applied. |

| t

| The bead of sealant must not be thicker than specified, otherwise excess sealant can enter the sump and obstruct the strainer in the oil intake pipe. |

| l

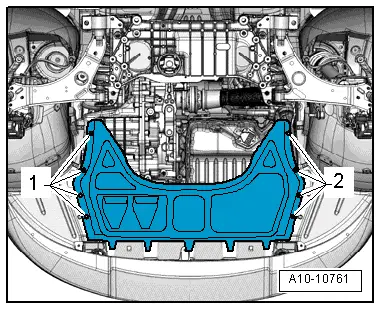

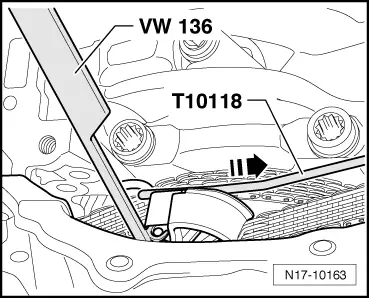

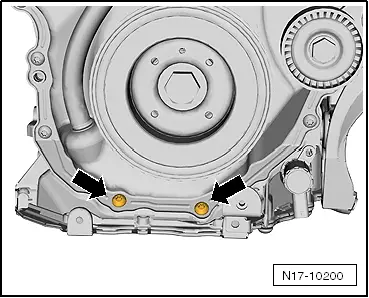

| The upper element of the oil sump and the crankshaft sump must connect flush on the gearbox side. |

|

|

|

Note

Note

Note

Note

DANGER!

DANGER! Caution

Caution