Leon Mk1

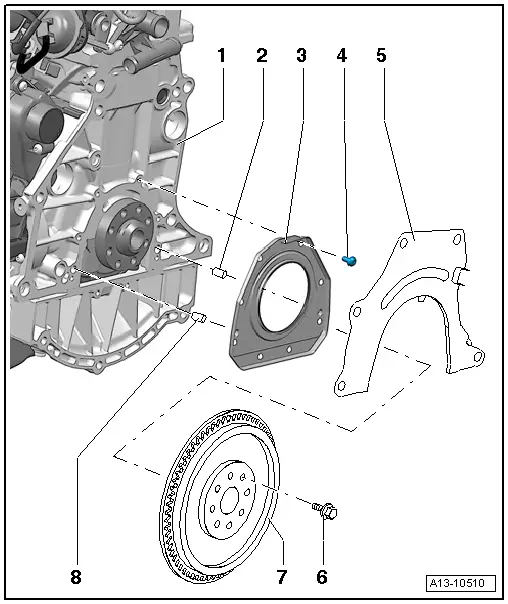

| Sealing flange (gearbox side) and dual-mass flywheel - exploded view |

| 1 - | cylinder block |

| q | Removing and installing crankshaft → Chapter. |

| q | Piston and conrod - assembly overview → Chapter |

| 2 - | Dowel pin |

| 3 - | Sealing flange, rear |

| q | With shaft seal |

| q | Only replace complete |

| q | To fit, use the guide sleeve provided |

| q | Removing and installing → Chapter. |

| q | Do not oil nor grease the sealing lip of the oil seal |

| q | Before fitting, use clean cloth to wipe off oil residue at crankshaft journal. |

| q | The guide sleeve should only be removed after fixing the sealing flange on the crankshaft journal |

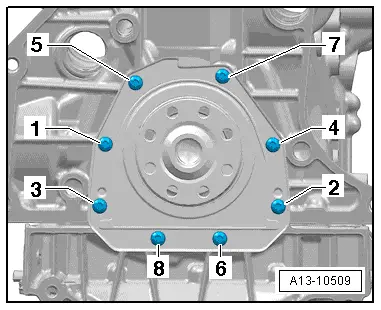

| 4 - | Bolt. |

| q | Tightening sequence → Fig. |

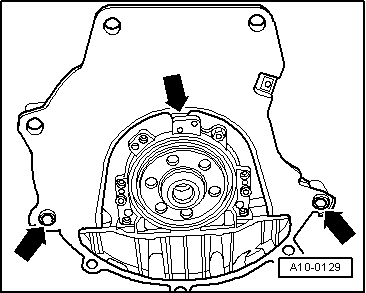

| 5 - | Intermediate plate |

| q | Must sit on dowel sleeves |

| q | Do not damage or bend when assembling. |

| q | Is fitted onto sealing flange → Fig. |

| 6 - | Bolt. |

| q | For the dual-mass flywheel/ drive plate |

| q | 60 + 90° (1/4 turn) |

| q | Replace |

| 7 - | Dual-mass flywheel |

| q | Removing and installing dual-mass flywheel → Chapter. |

| q | Can only be installed in one position. Holes are off-set |

| 8 - | Dowel pin |

|

|

|

|