Leon Mk1

|

| 1 - | Vibration damper |

| q | With poly V-belt pulley |

| q | Removing and installing → Chapter. |

| 2 - | O ring |

| q | Replace |

| 3 - | Bolt. |

| q | Replace |

| q | 150 Nm + further 1/4 (90°) |

| q | Loosen and tighten using the wrench -T10355- |

| 4 - | Poly-V belt |

| q | Check for wear |

| q | Do not kink |

| q | Removing and installing → Chapter. |

| q | When fitting ensure that it is correctly seated on the pulleys |

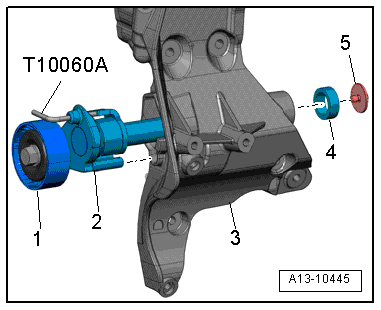

| 5 - | Poly V-belt tensioning element |

| q | Swivel with open-ended spanner to slacken poly V-belt |

| q | Immobilise using the retention tool -T10060 A- |

| q | Components of tension device for Poly-V belt → Fig. |

| q | Removing and installing → Chapter. |

| 6 - | Bracket for ancillary mechanical units |

| q | With oil filter and oil cooler |

| q | Removing and installing → Chapter. |

| q | Oil cooler: removing and fitting → Chapter |

| 7 - | Bolt. |

| q | 10 Nm. |

| 8 - | Alternator |

| q | Removing and installing → Rep. gr.27. |

| 9 - | Bolt. |

| q | 23 Nm. |

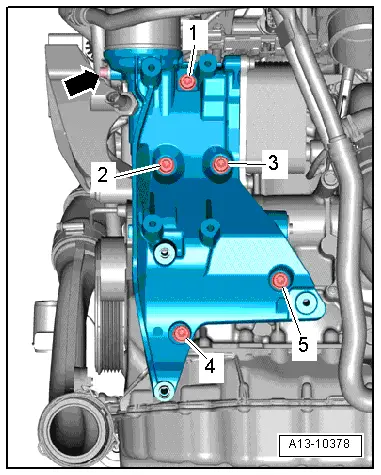

| 10 - | Bolt. |

| q | Tightening sequence → Fig. |

| 11 - | Air conditioning compressor |

| q | Do not unscrew or disconnect refrigerant hoses or pipes. |

| q | Removing and installing → Rep. gr.87. |

| 12 - | Bolt. |

| q | 25 Nm. |

| 13 - | Dowel sleeve |

| q | For air conditioner compressor |

|

|

|

|

|