| –

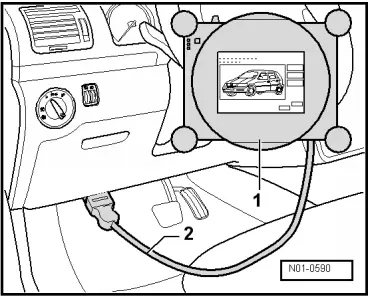

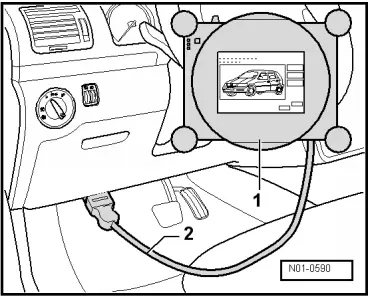

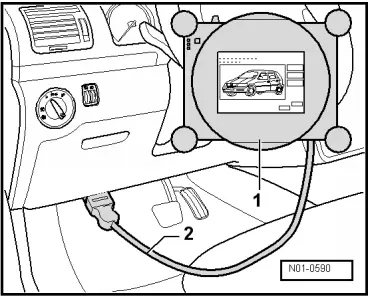

| Connect the vehicle diagnosis system as follows: |

| –

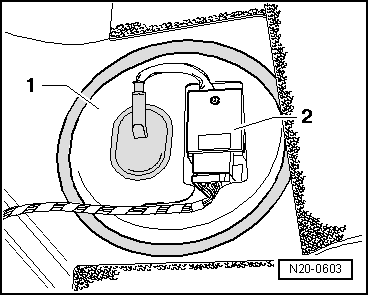

| Plug the connector 2 of the diagnosis cable into the diagnosis socket in the footwell on the driver's side. |

| –

| On the display, press the pushbuttons Vehicle self-diagnosis, Engine electronics and Actuator diagnosis one after another. |

| –

| Press the right-hand side button until the fuel pump electronic actuator diagnosis is selected. |

| The fuel pump should start running, first slowly and then gradually up to full power. |

Note | The fuel pump runs very quietly. |

| If the fuel pump does not run: |

| –

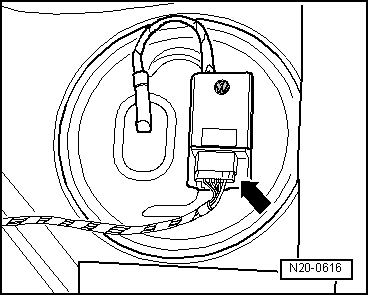

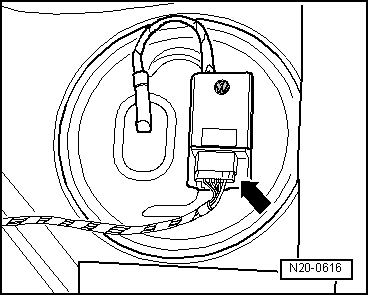

| Fold down the rear seat forwards. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note