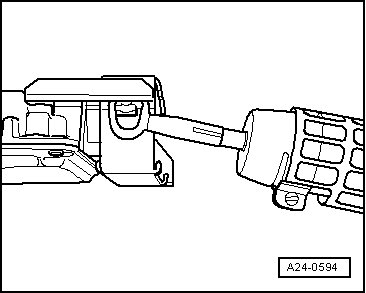

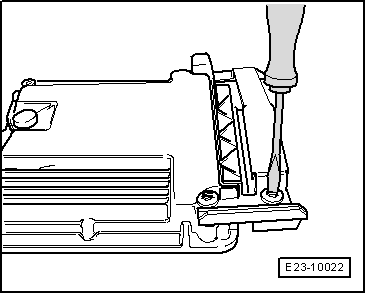

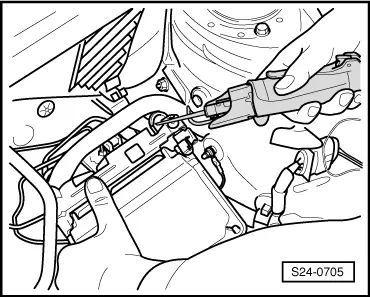

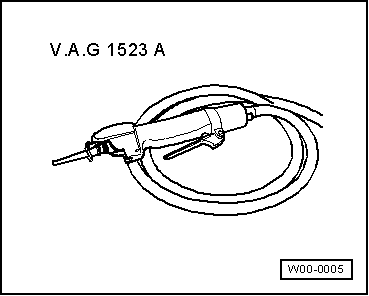

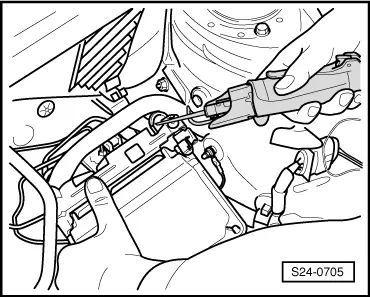

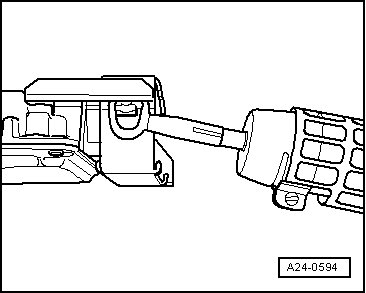

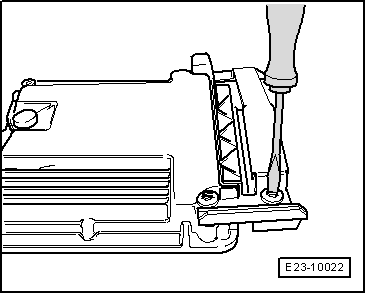

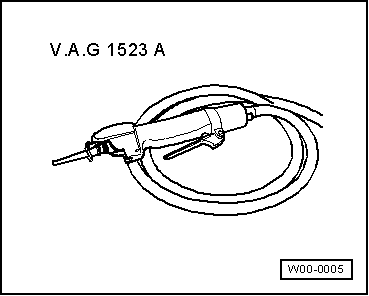

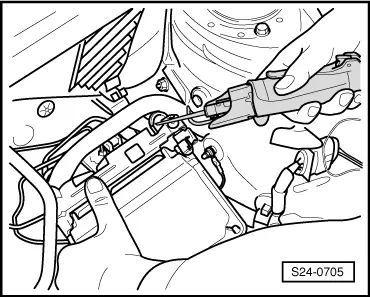

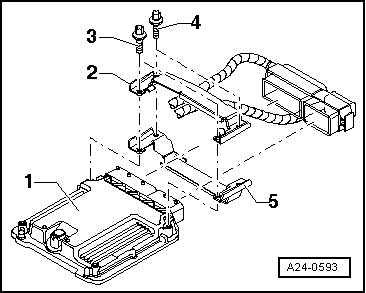

| Using the body saw -VAG 1523B- make a groove on the heads of the shear screws for inserting a screwdriver. |

Note | t

| The groove must be wide enough in order to be able to screw out the screws using an appropriate screwdriver. |

| t

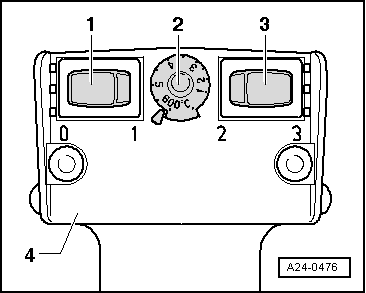

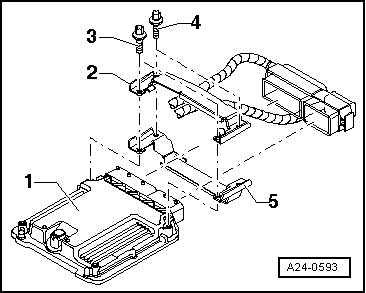

| The thread on the shear screws can been treated with a threadlocker. For making sure that unscrewing is easier, you can warm the shear screws using the Hot air blower -VAS 1978/14A-. In doing so, take care that no bordering cables, plugs or components are damaged! . |

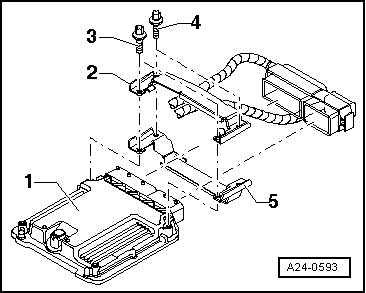

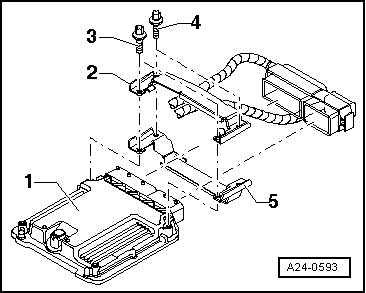

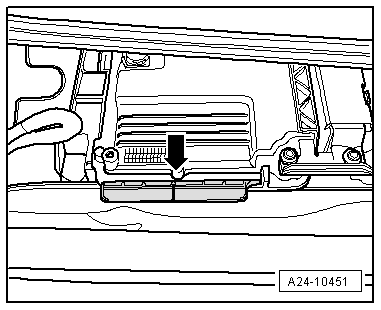

WARNING | The threads of the two shear screws which are screwed into the engine control unit are not secured with locking fluid. Do not apply heat to the threads in the control unit housing; this is not necessary and would cause overheating of the control unit. |

| The threads of the shear screws which are not screwed into the engine control unit are not secured with locking fluid. To unscrew these bolts, the threads must therefore be heated with the hot-air blower. |

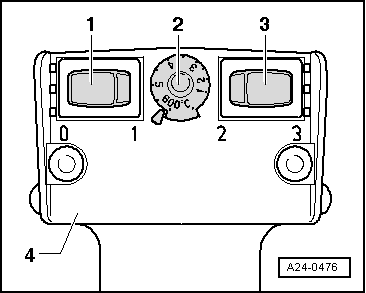

| To ensure that damage (burning) is not caused to the cables and connectors as well as insulation and control units, the following steps must be observed in all cases: Remember the instructions for using the hot-air gun. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note