Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

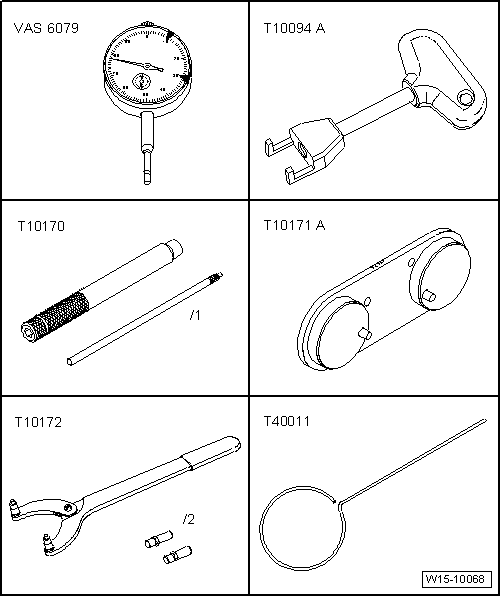

| Special tools and workshop equipment required |

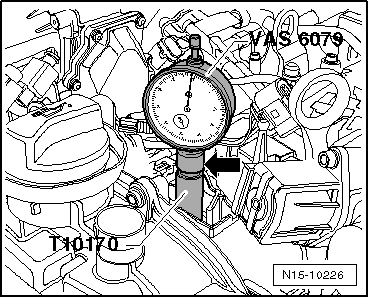

| t | Gauge -VAS 6079-, see equivalent → Anchor |

| t | Extractor -T10094A-, see equivalent → Anchor |

| t | Adjustment tool -T10170-, please see Correspondence → Anchor |

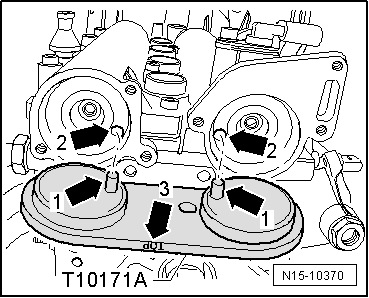

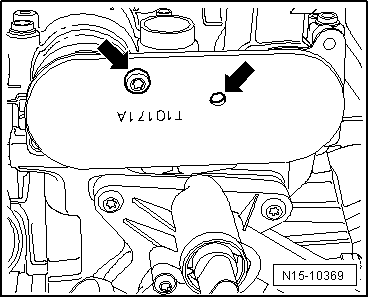

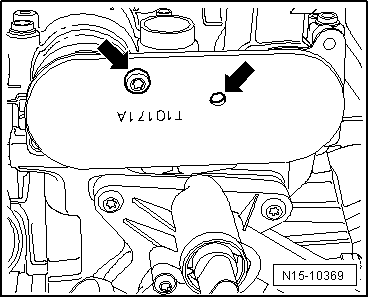

| t | Adjustment tool -T10171A-, please see Correspondence → Anchor |

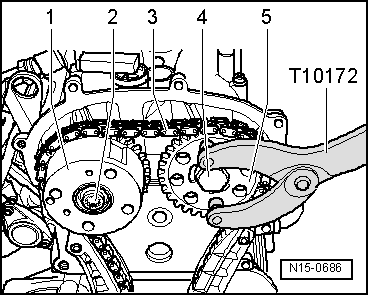

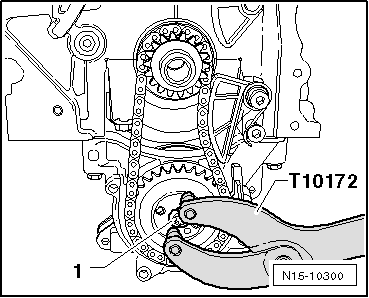

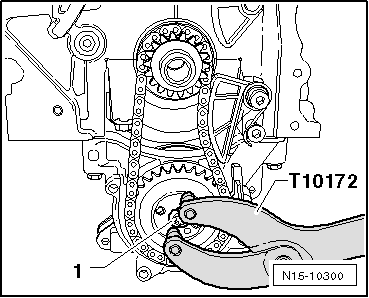

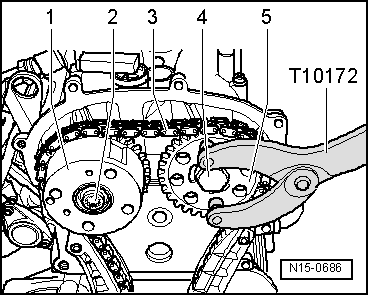

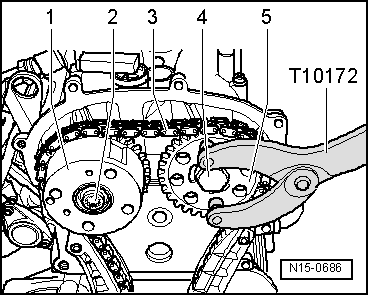

| t | counterhold -T10172-, see equivalent → Anchor |

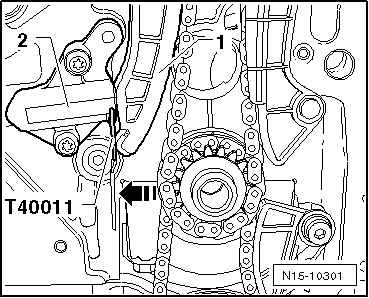

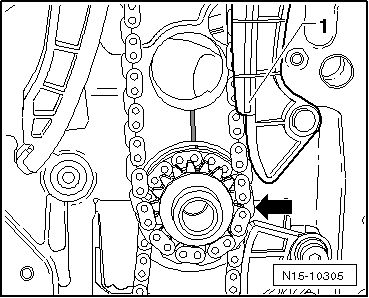

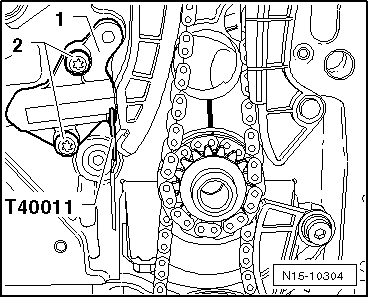

| t | Hose clamp -T40011-, see equivalent → Anchor |

| t | Spanner -3122B-, see equivalent → Anchor |

| t | Hose clamp -3415-, see equivalent → Anchor |

| t | Hose clamp -3415/1-, see equivalent → Anchor |

| t | Torque wrench -VAG 1331-, see equivalent → Anchor. |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

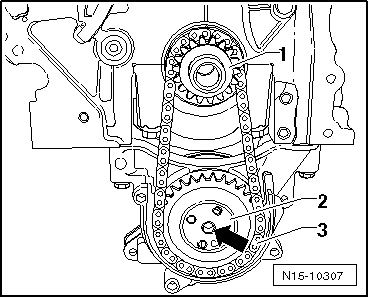

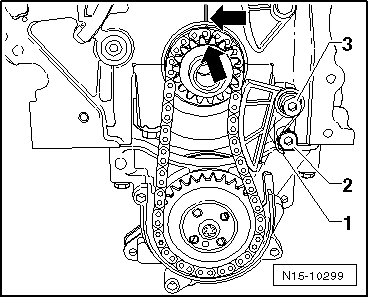

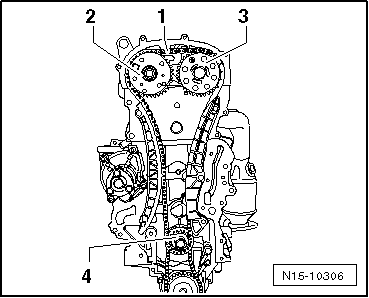

| Components: | Nm | |

| Screw of the gear sprocket of the oil pump | 20 Nm + retighten 1/4 turn (90º) | |

| Screw of the chain tensioner and drive chain of the oil pump | 15 | |

| Screw of the distribution chain tensioner | 9 | |

| Middle screw of the converter | 40 | |

| Screw of the camshaft gear wheels | 50 | |

| Oil pressure switch -F1- | 25 | |

Caution

Caution