| –

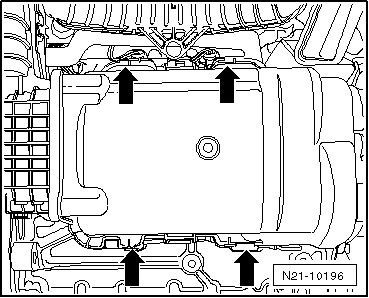

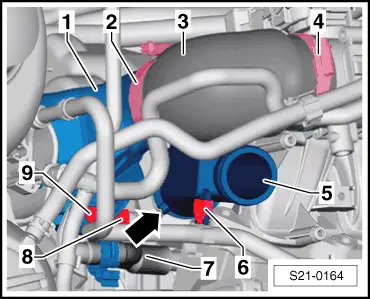

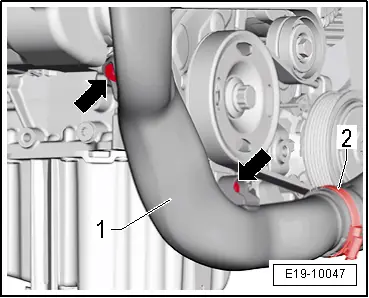

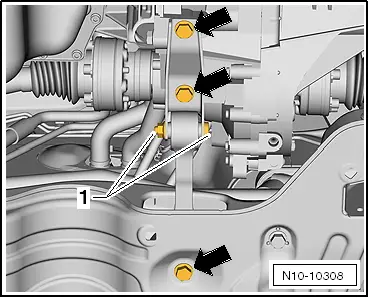

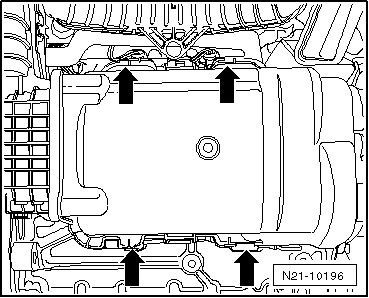

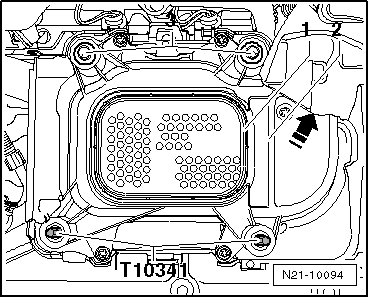

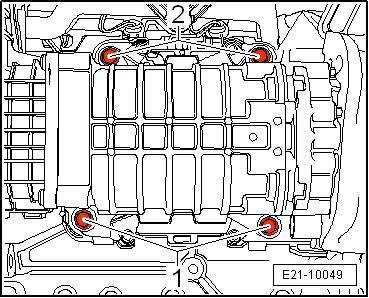

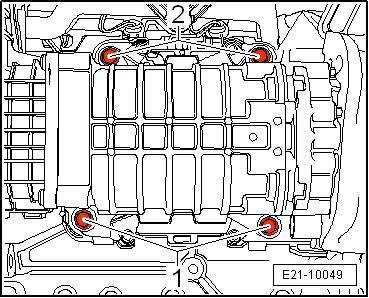

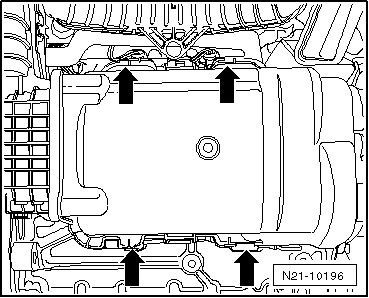

| Press housing together with noise insulation against supercharger until locking lugs -arrows- click into place. |

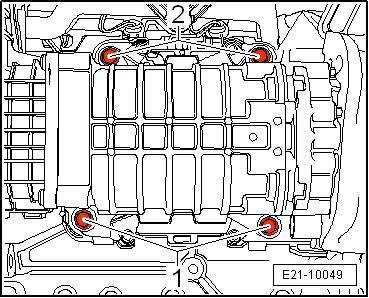

| The remaining installation steps are carried out in reverse sequence - note the following points: |

| t

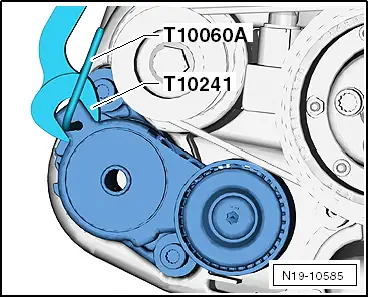

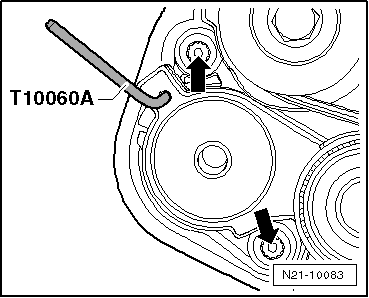

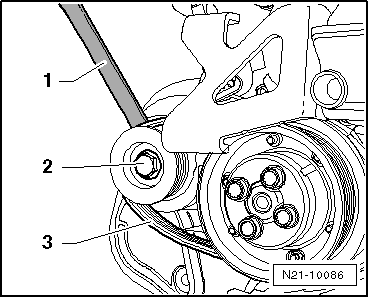

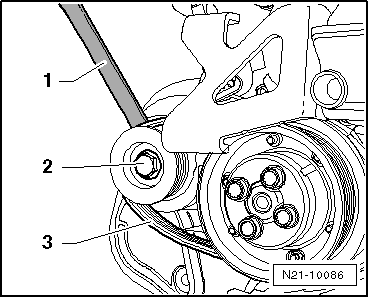

| Renew securing bolt for supercharger pulley. Tightening torque: 40 Nm +1/4 turn further (90°). |

| t

| Renew seals, gaskets and self-locking nuts. |

| t

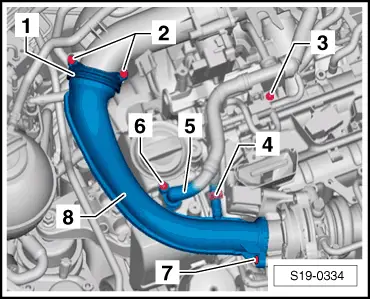

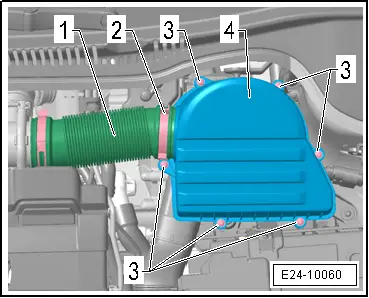

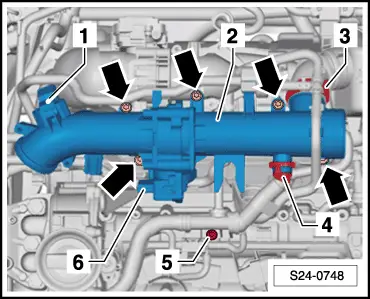

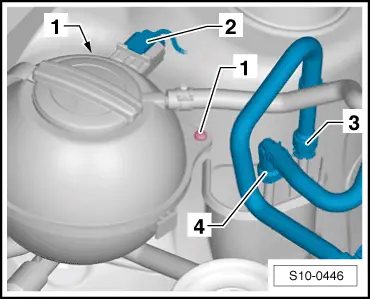

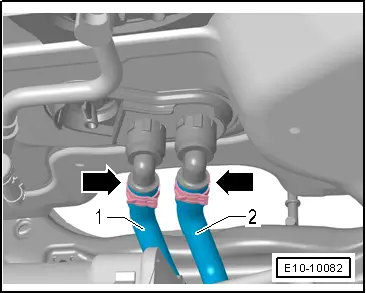

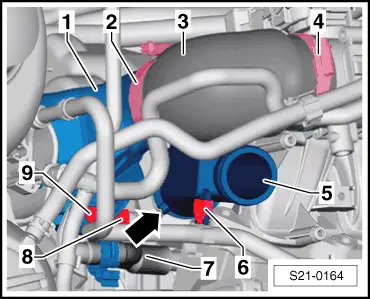

| Hose connections and hoses for charge air system must be free from oil and grease before fitting. |

| t

| Secure all hose connections with hose clips which conform to production standard. |

| –

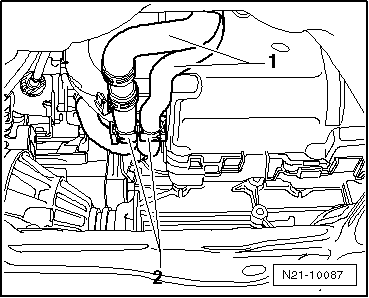

| Mount the primary catalytic converter with exhaust pipe → Chapter. |

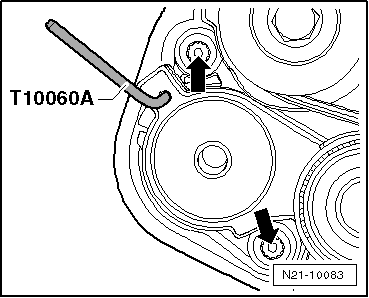

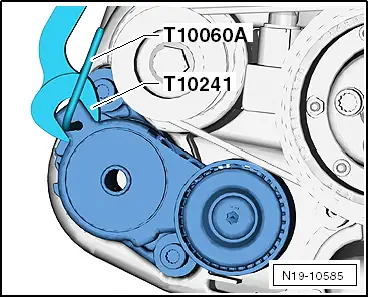

| Part I Poly V-belt drive - Assembly overview → Chapter |

| Catalytic converter and attaching parts - Assembly overview → Chapter |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution