Leon Mk1

| Distribution timing: adjustment |

| Special tools and workshop equipment required |

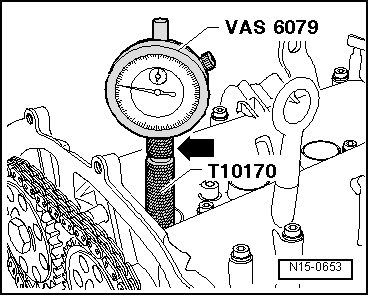

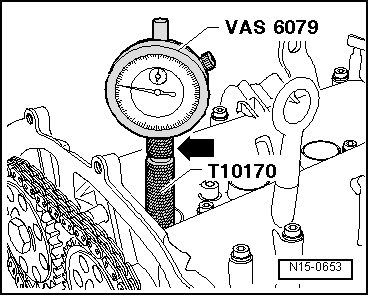

| t | Dial gauge -VAS 6079- |

| t | Extractor -T10094 A- |

| t | Dial gauge adapter -T10170- or dial gauge adapter -T10170 A- |

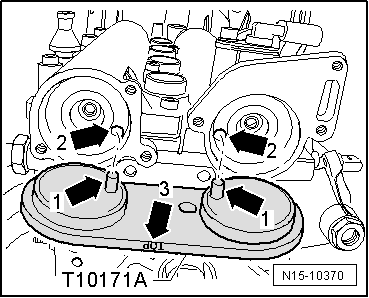

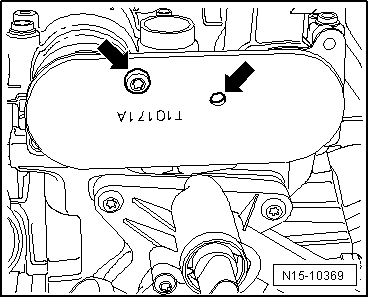

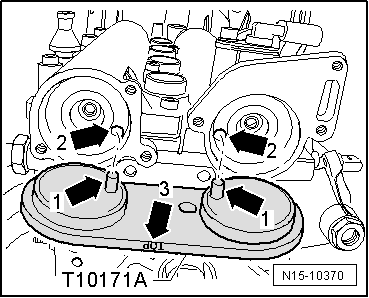

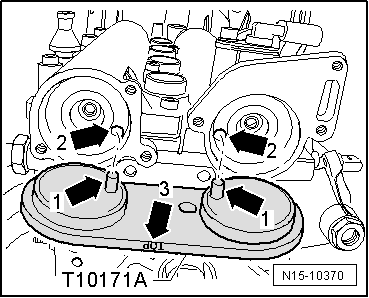

| t | Camshaft clamp -T10171 A- |

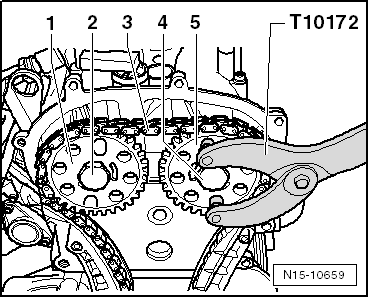

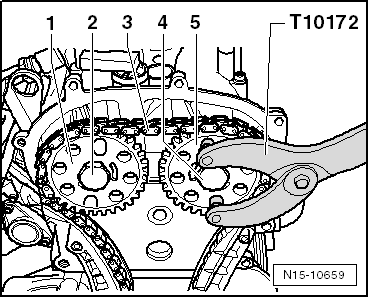

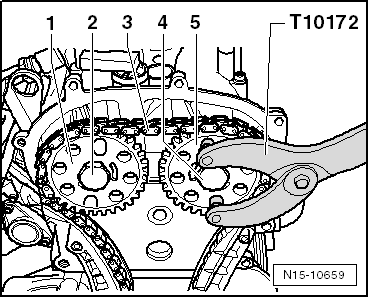

| t | Counterhold tool -T10172- |

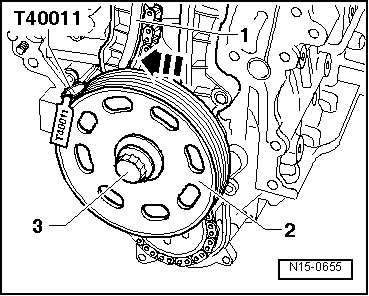

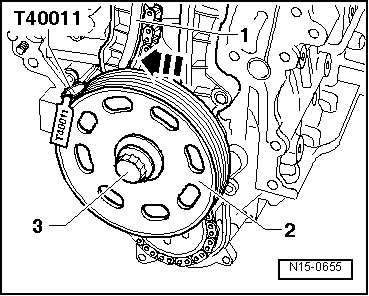

| t | Locking pin -T40011- |

| t | Torque wrench -V.A.G 1601- |

| t | Counterhold tool -3415- |

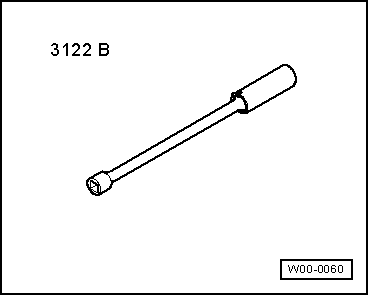

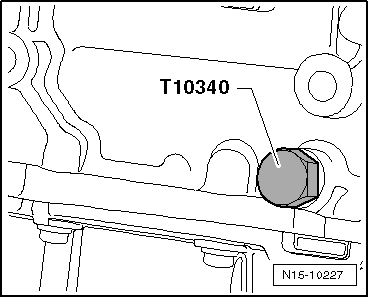

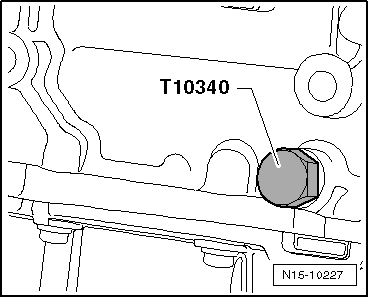

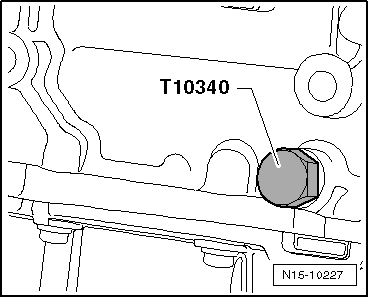

| t | Securing bolt -T10340- |

| t | Torque wrench -V.A.G 1331- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|