Leon Mk1

| Checking distribution timing |

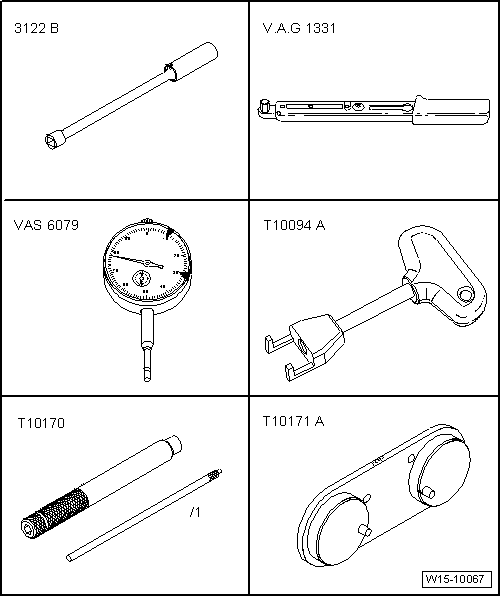

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

| t | Torque wrench (5…50 Nm) -V.A.G 1331- |

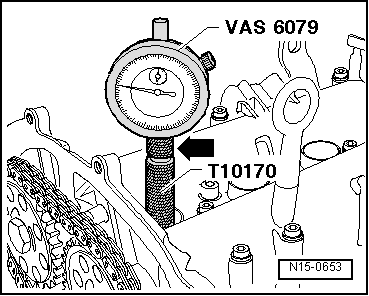

| t | Dial gauge -VAS 6079- |

| t | Extractor -T10094 A- |

| t | Dial gauge adapter -T10170- or dial gauge adapter -T10170 A- |

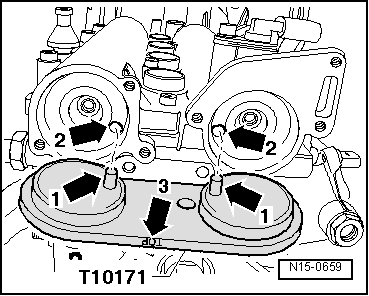

| t | Camshaft clamp -T10171 A- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|